20

EMR4 Terminal & Fueling Depot Installation

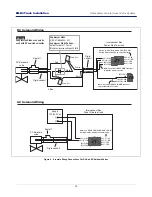

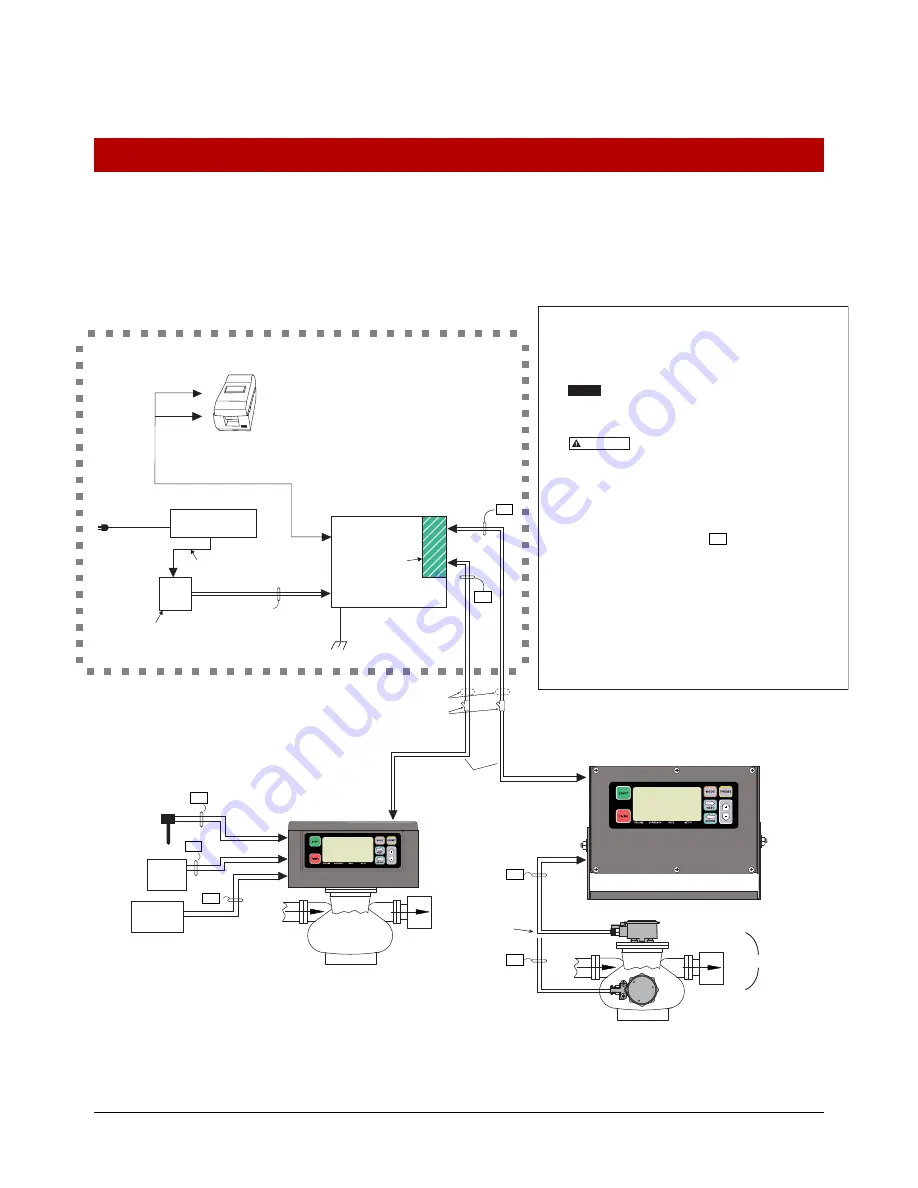

Installation of the EMR4 System involves installing the Display Head(s), installing the interconnect box, and

installing any optional devices (e.g., remote pulser, printer, etc.). This equipment must be installed according to the

applicable installation document. For UL/cUL installations use Control Drawing number 331940-021 and for

ATEX installations use Descriptive System Document number 331940-022. Figure 13 shows an example dual

Display Head installation.

Figure 13. Example Terminal Fueling Depot Installation With 2 Display Heads And Optional Remote Pulser

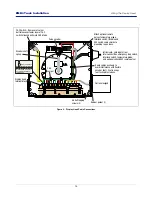

TERMINAL

OFFICE

HAZARDOUS

LOCATION

NON-HAZARDOUS

LOCATION

Rigid conduit

Interconnect

Box

Printer

D

a

t

a

(R

S

-2

3

2)

D

a

t

a

(R

S

-4

8

5)

D

a

t

a

(R

S

-4

8

5)

Power

Power

Power

120 or 240Vac

line cord

Se

a

l-off

UL

a

pproved 120W

i

s

ol

a

ted

s

econd

a

ry

Inp

u

t R

a

ting: 10–2

8

Vdc, 5 A

120 or 240Vac line

12 Vdc

Power

S

upply

Cu

s

tomer

s

upplied

wiring & rigid conduit

24 Vdc

Temp

Probe

UP

S

AC Power Protector

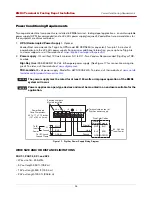

The following inform

a

tion i

s

for gener

a

l reference

a

nd i

s

not intended

to repl

a

ce recommended n

a

tion

a

l electric code (nec) proced

u

re

s

. it i

s

import

a

nt for the in

s

t

a

ller to

u

nder

s

t

a

nd th

a

t wiring loc

a

ted in Cl

ass

I,

Gro

u

p D Divi

s

ion 1

a

nd 2 in

s

t

a

ll

a

tion

s

or Cl

ass

I, Zone 0, Gro

u

p IIA

loc

a

tion

s

s

h

a

ll comply with the l

a

te

s

t

a

ppropri

a

te

a

rticle

s

fo

u

nd in the

N

a

tion

a

l Electric Code (NFPA 70).

Thi

s

i

s

a

control dr

a

wing only

a

nd doe

s

not reflect the

a

ct

ua

l

loc

a

tion

s

of cond

u

it entry. In In

s

t

a

ll

a

tion

a

nd

us

e of thi

s

prod

u

ct,

comply with the n

a

tion

a

l electric

a

l code; Feder

a

l,

S

t

a

te

a

nd Loc

a

l

Code

s

.

FAILURE TO COMPLY WITH THE FOLLOWING

WARNING

S

AND

S

AFETY PRECAUTION

S

COULD CAU

S

E

DAMAGE TO PROPERTY, ENVIRONMENT, RE

S

ULTING IN

S

ERIOU

S

INJURY OR DEATH.

The Di

s

play Head mu

s

t never be operated unle

ss

the front cover

and wirin

g

s

hield are clo

s

ed and properly

s

ealed over the barrier

terminal

s

in the intrin

s

ically

s

afe area of the Interconnect Box.

1. Intrin

s

ic

a

lly

sa

fe wiring (m

a

rked )

s

h

a

ll

b

e in

s

t

a

lled in

a

ccord

a

nce with Article 504 of the NEC, AN

S

I/NFPA 70.

2. In the non-intrin

s

ic

a

lly

sa

fe comp

a

rtment of the Interconnect Box,

connect the #12 AWG (4mm

2

) or l

a

rger di

a

meter

ba

rrier wire to

a

gro

u

nd l

u

g.

3

. To

m

a

int

a

in intrin

s

ic

sa

fety, di

s

pl

a

y he

a

d to interconnect

b

ox

wiring m

us

t

b

e r

u

n in dedic

a

ted cond

u

it. M

a

xim

u

m c

ab

le length i

s

1,000 feet (

3

04.

8

M).

4. Di

s

pl

a

y He

a

d m

us

t

b

e connected to e

a

rth gro

u

nd

thro

u

gh it

s

mo

u

nting

s

crew

s

.

Di

s

play Head 1

(Meter 1)

EPSON TM-U220A ROLL

Meter 2

Remote

Di

s

play Head 2

Top mount

Remote Pul

s

er

Front mount

Remote Pul

s

er

5 Vdc

P

u

l

s

e Inp

u

t

M

a

x. Remote

Pul

s

er c

ab

le

length 35 ft.

(10.6 m)

Meter 1

OR

M

a

x. c

ab

le length

1000 ft. (304.8 m)

I.S.

I.S.

I.S.

I.S.

I.S.

I.S.

I.S.

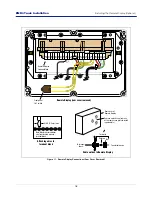

Connected to

E

a

rth Gro

u

nd

12 AWG U.

S

. (4mm2 E.U.)

B

a

rrier Gro

u

nd

WARNING

NOTICE

Intrin

s

ic

S

a

fety B

a

rrier

Interlock

S

witch

I.S.

E

SS

S

witch