Mag Probe Installation

Installing a LPG-ISO Mag Probe

35

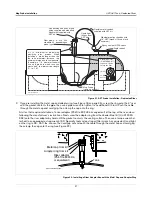

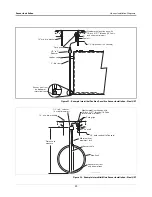

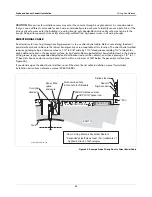

ATTACHING THE FLOAT TO THE TUBE

Slide the large shipping washer off of the stainless steel tube and discard it. Carefully slide the float, non-magnet

end first, onto the tube and down against the retaining ring at the bottom of the tube. The float must be installed

magnet-end up to measure fuel correctly (see Figure 28).

INSTALLING THE STAINLESS STEEL TUBE INTO THE TANK

With the float against the retaining ring, carefully lift the open end of the tube up and lower the assembly, float end

first, into the tank until the tube rests on the bottom of the tank (Figure 28). Carefully slide the 1” x 1-1/2” stainless

steel bushing, 1-1/2” end first, down over the tube until it rests against the tank opening. Apply UL classified

sealant suitable for use with LPG to the outside bushing threads that will be screwed into the tank fitting. Screw

the bushing into the tank fitting. Tighten the bushing as required to ensure a proper seal.

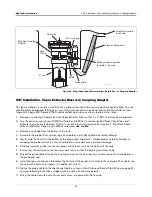

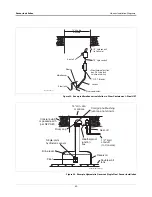

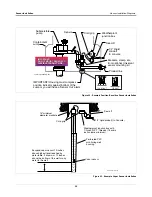

SEALING THE STAINLESS STEEL TUBE IN THE TANK OPENING

1.

Loosen the gland nut on the male connector. Carefully slide the male connector, 1” end first, down onto the

tube until it rests against the bushing. Apply UL classified sealant suitable for use with LPG to the threads of

the connector’s NPT threads. Screw the connector into the bushing. Tighten the connector as required to

ensure a proper seal.

2. Push the tube down until it rests on the tank’s bottom. Using a felt marker, make a mark on the tube at the top

of the gland nut. Raise the tube until the mark is 1-inch above the nut, then hand tighten the gland nut until the

tube is held in place (this distance is necessary for expansion and contraction of the tank). Tighten the gland

nut one and one-quarter full turns beyond hand tight to crimp the ferrules to the tube and create the proper

seal.

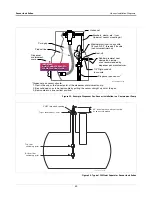

WARNING

The Veeder-Root Mag Plus probe is installed and operated in the highly combustible environment

of an LPG tank.

Fire or explosion resulting in serious injury or death could result if the equipment is improperly

installed or modified.

1. It is essential that you carefully read and follow the warnings and instructions in this manual

to protect yourself and others from serious injury due to fire or explosion. Failure to do so

could result in undetected potential environmental and health hazards.

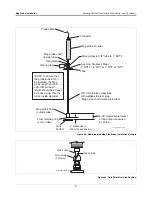

2. Comply with all federal, state, and local codes, and other applicable safety codes. All wiring

must comply with UL/CUL standards and other local electrical and pressure vessel codes.

3. All work on LPG systems must comply with NFPA 58, Liquefied Petroleum Gas Code and

other applicable code requirements.

4. LPG tanks must be depressurized (drained) and free of liquid and combustible vapors

before work begins. \

5. Failure to comply with these requirements could result in death, serious personal injury,

property loss, or equipment damage.

6. Substitution of components may impair intrinsic safety.

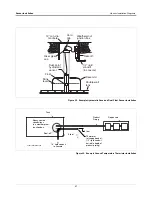

7. Circuitry within the probe and console barrier form an intrinsically safe, energy limited

system. The probe wiring is intrinsically safe only when connected to Veeder-Root consoles

having form numbers 8470, 8482, 8485, or 8560.