Connecting Probe/Sensor Wiring to Consoles

TLS-

3

50/ProMax/EMC Consoles

69

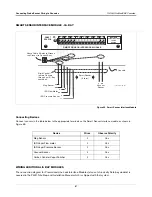

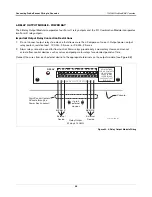

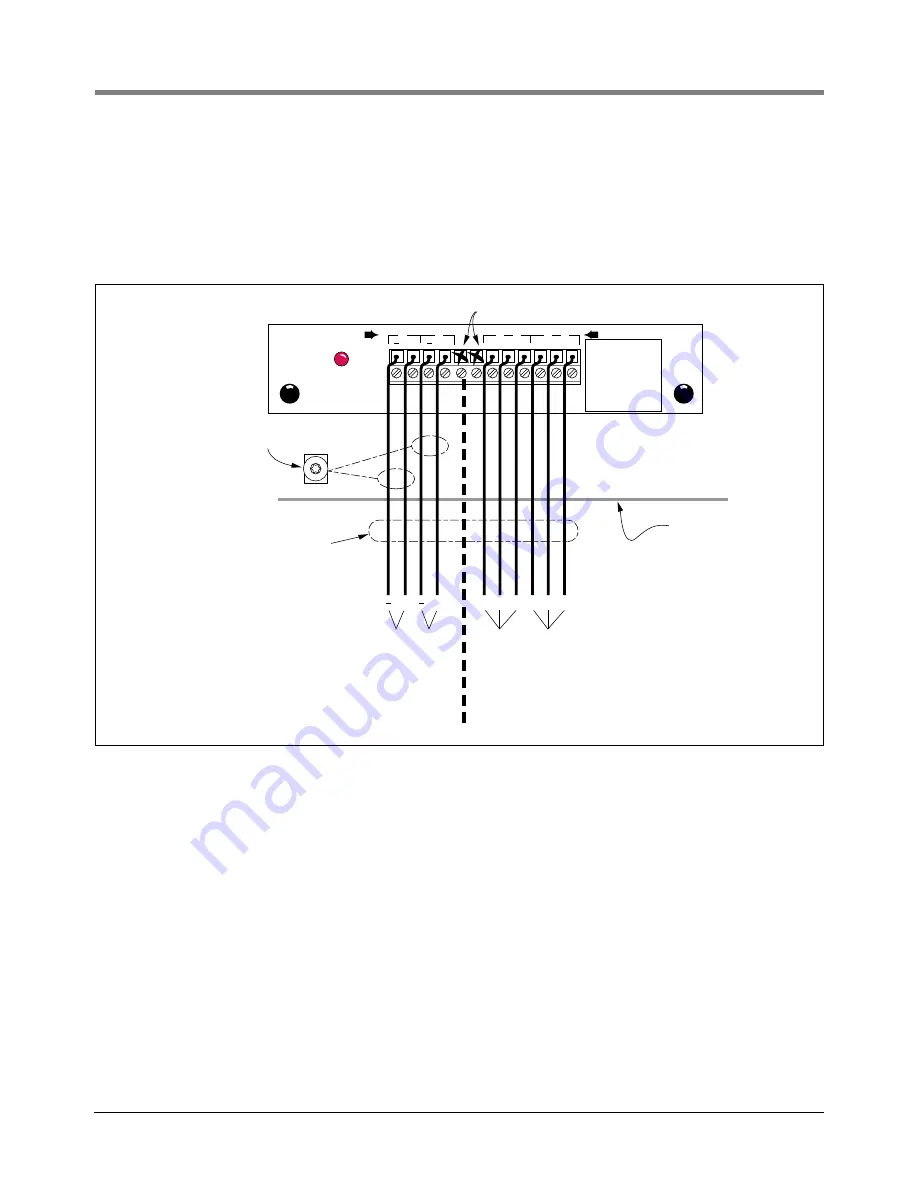

I/O COMBINATION MODULE - POWER BAY

The I/O Combination Module can accept two dry-contact switch closure inputs from an external device such as a

line leak detector or well monitoring system [Figure 67].]

For each external input, connect a shielded cable consisting of two #18 AWG conductors to the appropriate input

terminals on the module.

Figure 67. I/O Combination Module Wiring

INPUT

I/O COMBINATION MODULE

RELAY

consoles\iocmw.eps

Console

Attach Cable Shield to Ground

Lug Closest to Conduit Entry

+

+

Input

Input

Shielded

Cables

External Input

Wiring

#18 AWG

NC NO C

External

Device

Relay Output

Wiring

#14 AWG

NC NO C

External

Device

Not Used

Rigid Conduit (enters

Console through a

Power Bay knockout)

+

+

1

2

3

NC NO C

3

NC NO C

4

4

RELAY RATINGS

FORM C CONTACTS

120 VAC 2A MAX

24 VDC 2A MAX

FUSE RATINGS

2A 250VAC TYPE T

(SLO-BLO)