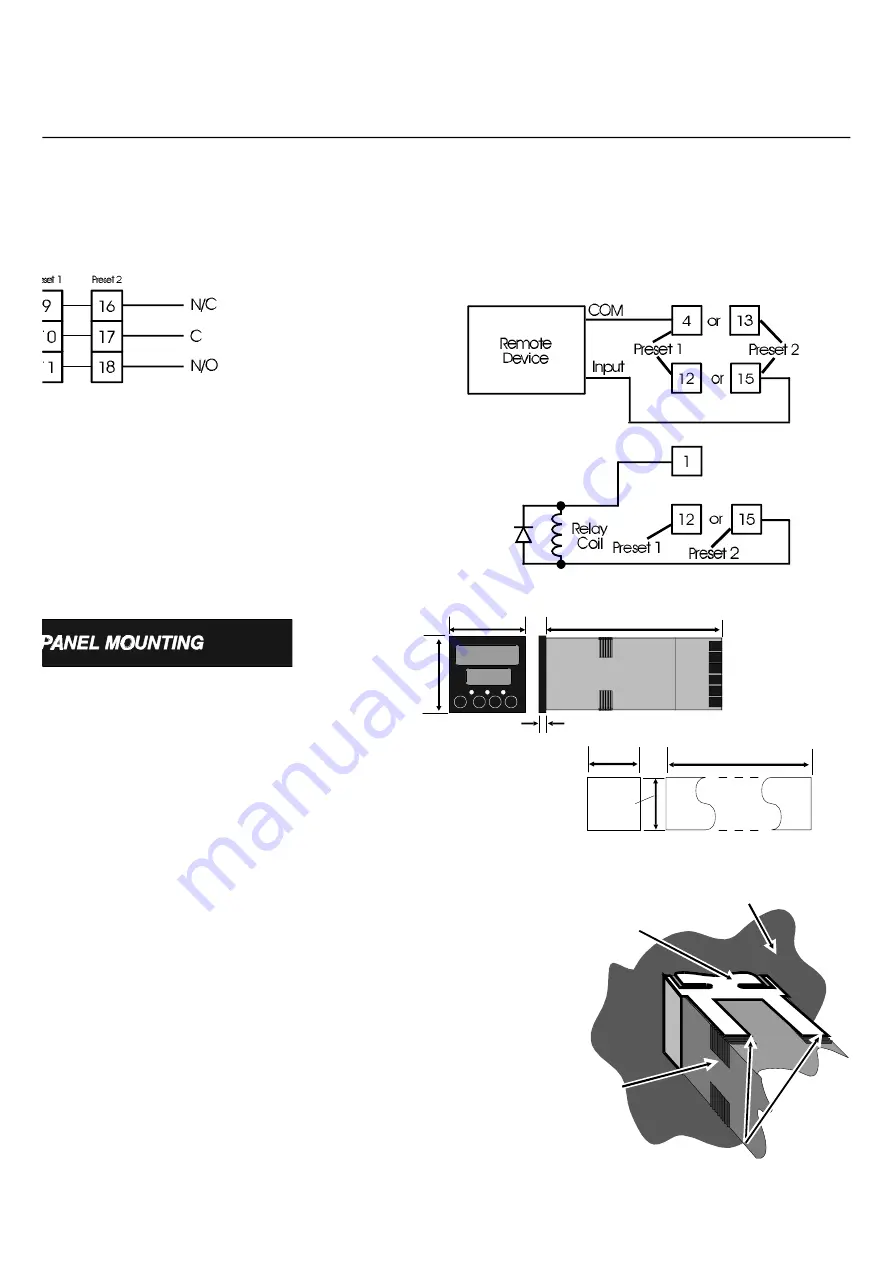

Open Collector Output

Connect Terminals 12 (Preset 1 open collector) and 4 (COM) or 15

(Preset 2 Open Collector) and 13 (COM) to solid state devices as

below (upper circuit). To drive DC relay coils, connect Terminal 12

or 15 and V+ (Terminal 1) as below (lower circuit). Suppress

switching transients with a suppression diode, connected as shown.

48m

48m

10mm (approx.)

110

45m

45m

(48n - 4)mm

Single

Installatio

Multiple Installation (n

Counters)

Panel Mounting

Make cut-out(s) according to the details in

the diagram on the right. The maximum

panel thickness is 6 mm.

Rear face of mounting panel

Mounting bracket

Counter

housing

Tongues on mounting bracket

engage in ratchet slots on Counter housing

Insert the rear of the Counter housing

through the cut-out (from the front of the

mounting panel) and hold the Counter

lightly in position against the panel. Ensure

that the panel gasket is not distorted and that

the Controller is positioned squarely against

the mounting panel.

Apply pressure to the

front panel bezel only.

Slide the mounting

bracket in place (see right) and push it

forward until it is firmly in contact with the

rear face of the mounting panel (tongues on

the bracket should engage in matching

rachet positions on the Counter housing and

the mounting bracket springs should push

firmly against the mounting panel rear face).

CAUTION

Do not remove the panel

gasket from the Counter as

this may result in

inadequate clamping of the

Counter in the mounting

panel.

I N S T A L L A T I O N

Relay Output

Connect AC or DC load circuits to Terminals 9, 10 & 11

(Preset 1) or 16,17 & 18 (Preset 2) (see below) as required.

Do not route load wiring near count input or transistor output

signals.

Summary of Contents for V454502

Page 10: ...10 N O T E S ...

Page 11: ...11 N O T E S ...