16

E7

Electrical connections

Connection to the power supply must be carried out in

conformity with the current regulations and provisions in

the country of use.

•

Make sure the machine power supply voltage speci-

fied on the rating plate (Table 1) matches the mains

voltage.

•

Make sure the system power supply is arranged and

able to take the actual current load and that it is exe-

cuted in a workmanlike manner according to the reg-

ulations in force in the country of use.

•

The earth wire at the terminal end must be longer

(max. 3/4” [20 mm]) than the phase wires.

•

Connect the earth wire of the power supply cable to

an efficient earth clamp. The appliance must also be

included in a unipotential system, the connection

being made through the screw “EQ” (see pargraph

E6.2 Installation diagram) marked with the symbol

“

”. The unipotential wire must have a cross section

of 10 mm

2

.

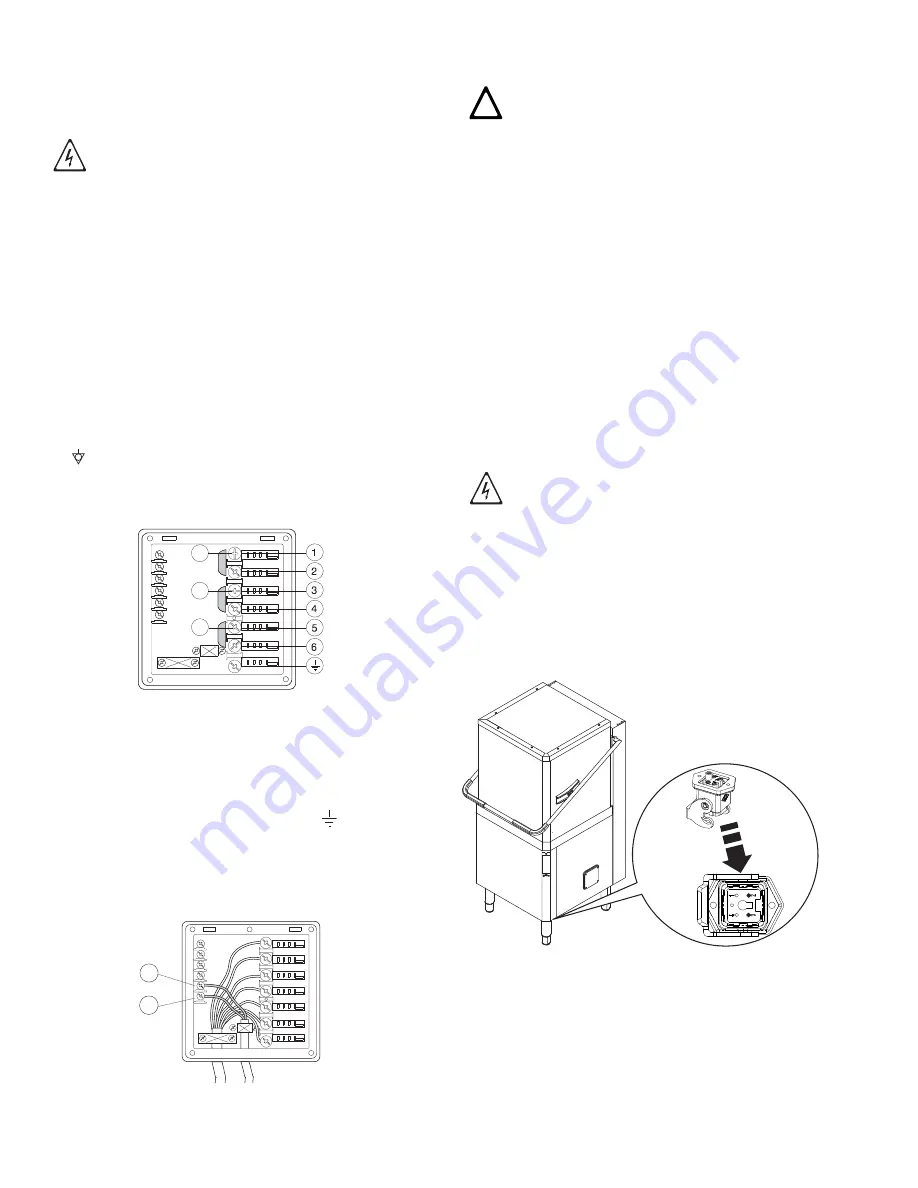

Power supply 208V 3ph or 240V 3ph

Figure 11 208V 3ph o 240V 3ph

Open the power supply terminal board and insert the jum-

pers provided as follows: one jumper between terminals 1

and 2, one between terminals 3 and 4 and another between

terminals 5 and 6. Using a suitable power supply cable (see

technical data table), connect the three phases to terminals

1, 3 and 5 and the earth wire to the terminal

.

E8

Energy control arrangement

The machine is arranged for external control of energy

consumption.

Figure 12 Energy control

Connect the energy peak controller across terminals 11

and 12 (Figure 12).

Safety devices

•

An automatic reset thermoamperometric protective

device incorporated in the windings of the electric

pump cuts off the electricity supply in the case of mal-

functioning.

•

In the event of water mains failure, a device prevents

water in the boiler from returning into the mains.

•

An overflow pipe, connected to the drainage outlet,

maintains the water in the tank at a constant level.

Failure to comply with safety rules and regulations

relieves the manufacturer of all liability.

E9

HACCP arrangement

The machine is arranged for the HACCP connection it is

still necessary to order the network connection cable.

Connect the HACCP network to terminals 2 and 3 of

connector X4.

Figure 13 HACCP connection position

IMPORTANT!

Work on the electrical systems must only

be carried out by a qualified electrician.

L1

L2

L3

11

12

CAUTION

A normally open (n.o.) contact of the con-

troller must be connected across termi-

nals 11 and 12. When this contact closes

the boiler heating elements are discon-

nected. Using the dishwasher in these

conditions may increase the cycle time.

IMPORTANT!

If the power cable is damaged it must be

replaced by the After-Sales Service or in

any case by qualified personnel, in order

prevent any risk.

!