14

•

The appliance must be fixed to the floor using the two

clamps supplied (Figure 9).

Figure 9 Machine fixing clamp

•

Accessing the appliance bottom panel.

•

Fit the clamps on feet as shown in supplied technical

sheet.

•

Screw the appliance steadily to the floor using hole

clamps.

E5

Disposal of packing

All materials used for packing are environmentally com-

patible. They can be safely kept, and recycled or burnt in

a special waste incineration plant. Plastic parts subject

to possible recycling are marked as follows:

Parts in wood and cardboard can be disposed of

respecting the current regulations in the country of use.

E6

Plumbing connections

IMPORTANT

Watermark labelled machines must be installed in

accordance with AS/NZS 3500.1.

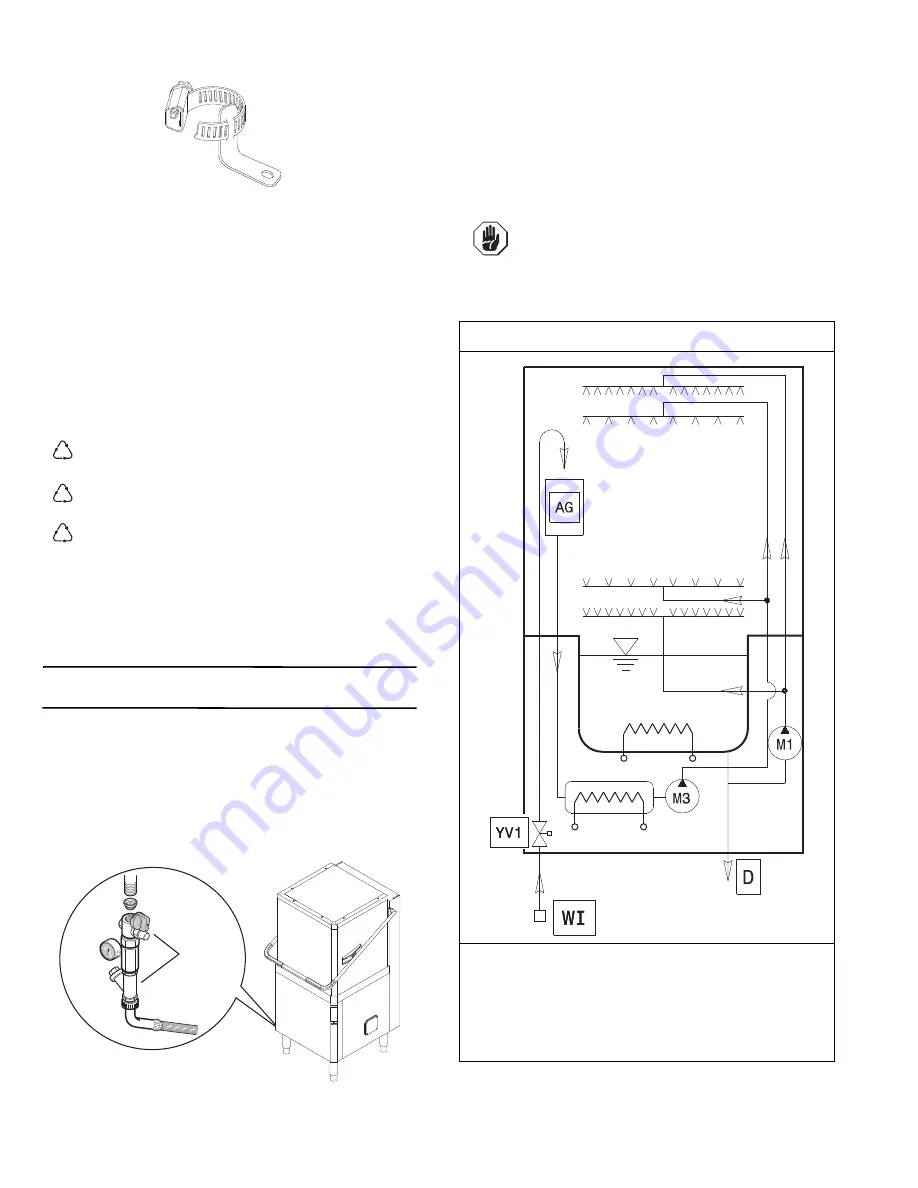

Install the machine water filling and drain pipes according to

the plumbing circuit and installation diagrams given below.

•

Connect the appliance water supply pipe “WI” (see

paragraph E6.2 Installation diagram) to the mains, fit-

ting a cut-off valve, the filter provided and a pressure

gauge between the appliance and the mains

(Figure 10).

Figure 10 Feed pipe connection

•

Check that the

dynamic

water supply

pressure

,

measured between the appliance and the main, is

between 7.25 and 101 psi (50 and 700 kPa)

(test

while dishwasher tank or boiler is filling with water).

If the pressure is too high, fit a suitable pressure

reducer on the inlet pipe.

•

Connect the waste outlet pipe “D” (see pargraph E6.2

Installation diagram) to the main drain pipe, fitting a trap,

or place the outlet pipe over an S trap set into the floor.

E6.1

Plumbing circuits

polyethylene:

outer wrapping, instruc-

tion booklet bag.

polypropylene:

roof packing panels,

straps.

polystyrene foam:

corner protectors.

PE

PP

PS

!

IMPORTANT!

Always use a new set of joints if you

remove and reinstall the water inlet pipe

to the appliance.

Plumbing circuit diagram

LEGEND

WI =

Water inlet

M1 =

Wash pump

M3 =

Rinse pump

AG =

Air Gap

YV1 = Filling solenoid valve