ENGLISH

27

•

Switch off the dishwasher by pressing button “A”

(Table 2 “Control panel”).

•

Switch off at the mains.

•

Close the water supply valve.

•

Replace the filter and the overflow.

Cleaning the nozzle jets

•

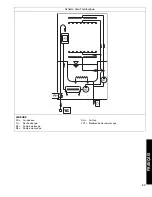

Remove the upper and lower wash arms "1" and

rinse arms "2", undoing the ring nut "3" (Figure 24).

•

Carefully clean the washing and rinse jets and clean

everything with hot water and neutral detergent/deter-

sive, if necessary using a soft brush or sponge. Do

not use sharp implements to clean the nozzle holes,

which could otherwise be damaged.

Upon completion of cleaning operations, replace the

parts removed previously.

I8.2

Exterior cleaning

Before carrying out any cleaning operations, turn off the

power at the mains.

IMPORTANT

Clean the stainless steel surfaces using warm soapy

water; never use detergents containing abrasive

substances nor steel scrapers, common wire wool,

brushes or scrapers; rinse thoroughly using a wet

cloth and carefully wipe dry.

Clean the control panel using a soft damp cloth and

a neutral detergent if necessary.

Do not wash the appliance using direct or high-pres-

sure water jets.

To reduce the emission of pollutants into the environ-

ment, clean the appliance (externally and where neces-

sary internally) with products having a biodegradability of

over 90%. Leave the hood raised whenever the

appliance is not in use.

I9

Long idle periods

Whenever the dishwasher is not going to be used for a

long period of time (e.g. one month), carefully carry out

the following instructions.

•

Close the water supply valve.

•

Completely drain the tank.

•

Remove and carefully clean the filters.

•

Completely drain the incorporated dispenser hoses,

removing them from the containers. Repeat the pro-

cedure described in the paragraph “Manual activa-

tion” at least 3 times.

•

Completely drain the boiler.

•

Clean the inside and outside of the machine as indi-

cated in par. I8.1 “End of service and daily internal

cleaning” and I8.2 “Exterior cleaning”.

•

Spread a film of paraffin oil over the steel surfaces.

When using the machine again, follow the indications in

par. I4 “Daily activation of machine”.

I10

Maintenance

Inspection and maintenance intervals depend on the

actual machine operating conditions (total wash hours)

and ambient conditions (presence of dust, damp, etc.),

therefore precise time intervals cannot be given. In any

case, to minimize interruptions of the service, careful

and periodical machine maintenance is advisable.

Therefore, it is advisable to:

•

Descale the boiler, inside surfaces of the tank and the

machine piping once or twice a year (call technical

assistance).

•

Every month descale the wash and rinse jets with

vinegar or scale remover.

•

The internal hose of the rinse-aid and detergent peri-

staltic dispenser should undergo periodic mainte-

nance (once or twice a year).

•

If present, clean the finned coil of the energy saving

device once or twice a year (call technical assis-

tance).

It is also advisable to stipulate a scheduled preven-

tive maintenance contract with technical assistance.

I10.1

Preventive maintenance

The preventive maintenance call can be activated (call

technical assistance).

On reaching the set number of cycles (e.g. 20000), a

technical assistance call message appears on the dis-

play. This message suggests calling a specialized tech-

nician, for a general check of the equipment.

Figure 24 Wash and rinse arms

3

1

2