DOC. NO. 5956.6K6.00

P. 15 / 28

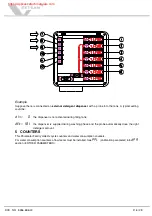

8.4

Configuration Parameters

Sym.

Parameter Description

Unit

Min

Max

Factory

Default

Dishwasher Model:

0 = UNDERCOUNTER

1 = POT WASHER

2 = AUTOMATIC POT WASHER

3 = MEDICAL LINE DISHWASHER WITH LOCK DOOR/HOOD

DEVICE

-

0

3

0

Boiler type:

0 = ATMOSPHERIC BOILER

1 = PRESSURE BOILER

2 = EXTERNAL BOILER

-

0

2

0

Door type:

0 = AUTOMATIC HOOD

1 = MANUAL HOOD

2 = FRONT LOADING

3 = POT WASHER

0

3

2

Default model (see Default tables):

1 = HOOD TYPE

2 = POT WASHER

3 = UNDERCOUNTER

-

0

3

-

Solid State Relay (TRIAC).

0 = not enabled;

1 =

SOFT START

enabled;

3 =

SLOW SOFT START

enabled

(works only on boards with Solid State Relay)

.

-

0

3

1

Boiler/Tank heating swap:

0 = boiler heaters and tank heater can work simultaneously;

1 = swap enabled: tank heating starts only boiler temperature is

reached;

2 = The booster heating elements and the wash pump have prior-

ity. The tank heating element is activated only when the booster

has reached the set temperature and the wash pump is not work-

ing.

(Note: disabling this function changes the global electrical power

of appliance; before enabling this function check available power,

supply cable section, fuses in according to User Manual).

-

0

2

1

Tank Filling Mode

Enable filling tank by means of rinsing cycles

.

Ex:

= 167 means that boiler water is heated at 167°F, then

follows a rinse phase and so on until tank is full.

If

= 32 the tank is filled by solenoid valve in the traditional

way (On machines with incorporated continuous water softener,

even if

is set to 32, filling occurs through subsequent

rinses).

[°F]

32

185

167

Detergent Level Switches

0 = level switches not enabled;

1 = enable detergent level switches;

-

0

1

0

USER INTERFACE MODEL

24 = under counter, Veetsan

See parameter

(family

)

to check the software version

installed in the board.

-

0

27

25