DSGH Installation and Operation Guide

17

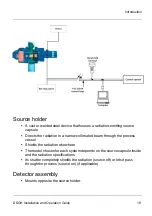

Introduction

* Power specifications change if an internal heater kit is used.

Typical applications

VEGA’s density gauges accurately indicate:

• Density of liquids or slurries through a pipe or vessel wall without contact

to the material

• Percent of solids in a carrier

• Interface between liquids flowing in a pipe, when the liquids differ in

density

Weight

Housing

detector

5.44 kg (12 lb)

Current

Loop

Output

Rating

4 mA ... 20 mA, isolated, into 250 – 800

Power

Jumper selectable: source (active) or sink

(passive) mode

Relay

Output

Software

user-

settleable

Diagnostic alarm or process high/low alarm

function

Rating

6 A at 240 VAC, or 6 A 24 VDC (SPDT Form C),

or 1/4 HP at 120 VAC

HART

®

Communic

ation

HART

Protocol

BEL202 FSK standard current loop output

PC interface

HART modem and VEGA communications

software

Optional

hand-held

interface

Emerson Field Communicator model 375 with

VEGA device descriptions loaded

Auxiliary

Input

Capability

Type

Frequency input (0 ... 100 kHz)

Possible

function

Optional Mass Flow or Temperature

compensation, multiple gauge linking, and others

Electronics

On-board

memory

FLASH and 2 EEPROMs

Real-time

clock

Maintains time, date, source decay

compensation, and is Y2K compatible

Diagnostic

s

LED

indication

+6V, Memory Corruption, HART, CPU Active,

Auxiliary, High Voltage, Relay and Field Strength

Table 1.1

DSGH specifications (continued)

Summary of Contents for DSGH

Page 2: ......

Page 4: ...2 DSGH Installation and Operation Guide NOTES ...

Page 8: ...6 DSGH Installation and Operation Guide NOTES ...

Page 12: ...10 DSGH Installation and Operation Guide Preface NOTES ...

Page 32: ...30 DSGH Installation and Operation Guide Installation Mounting the DSGH gauge ...

Page 56: ...54 DSGH Installation and Operation Guide Calibration NOTES ...

Page 94: ...92 DSGH Installation and Operation Guide Diagnostics and repair NOTES ...

Page 98: ...96 DSGH Installation and Operation Guide NOTES ...

Page 99: ......