16

5 Set up the sensor with the display and adjustment module

VEGAPULS SR 68 • Modbus and Levelmaster protocol

47164-EN-140129

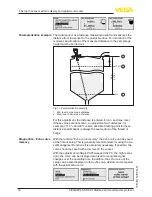

The radar sensor as a distance measuring instrument measures the

distance from the sensor to the product surface. For indication of the

real level, an allocation of the measured distance to the percentage

height must be carried out.

2

1

3

100%

0%

1

m

(39.37

")

35

m

(1378

")

Fig. 11: Parameterization example

1 Min. level

≙

max. meas. distance

2 Max. level

≙

min. meas. distance

For this adjustment, the distance is entered for min. and max. level.

If these values are not known, an adjustment with distances, for

example, of 10 % and 90 % is also possible. Starting point for these

distance specifications is always the seal surface of the thread or

flange.

With the function "

Echo curve memory

" the echo curve can be saved

at the time of setup. This is generally recommended; for using the As-

set Management functions it is absolutely necessary. If possible, the

curve should be saved with a low level in the vessel.

With the adjustment software PACTware and the PC, the high resolu

-

tion echo curve can be displayed and used to recognize signal

changes over the operating time. In addition, the echo curve of the

setup can be also displayed in the echo curve window and compared

with the actual echo curve.

Parameterization example

Diagnostics - Echo curve

memory