63138-US-200110

45

Shutter (ON/OFF) Mechanism (required every six months)

Depending upon whether or not your source holder uses a shutter or cable

mechanism, checks are normally performed at intervals not to exceed six months.

To test the shutter mechanism, move the actuator back and forth several times

between the OFF and ON positions.

Customers who have the ability to cycle shutters or check cables on a more

frequent basis without disturbing production requirements are recommended to

do so. The application of lubricating oil to the shutter mechanism will assist in

maintaining the source holder in good working order.

There are no ON/OFF indicators to verify that the shutter or cable mechanism is

working correctly or that

the source is in the shielded position. When the source

shutter or positioning cable is in the retracted position and the shutter is closed, it

is assumed that the source is in the shielded position. Monitoring of the radiation

levels by level detectors or other means is necessary to ensure that the source is

in the shielded position and not in the source well.

Keep the records of these tests, listing the date and name of the person

performing the test, for at least three years.

At the first indication that a shutter or cable mechanism is not working properly,

contact the manufacturer for advice. A sticky shutter or a cable that will not retract

is a warning that the proper operation is compromised and you need to address

the inoperable mechanism.

If the shutter or cable mechanism becomes inoperable, contact your regulator

and manufacturer immediately for advice. DO NOT attempt to free up the shutter

or cable by mechanical means with the use of wrenches, hammers, channel locks,

levers, etc. These devices may cause more damage and are prohibited. Such

actions have been known to shear the source cable.

If a device has an inoperable shutter or cable, the source holder should not be

removed without consulting the manufacturer.

The actuator should move easily, but not freely. There will be some

resistance to movement

due

to

bearing

friction

and

inertia

of

the

mechanism

.

!

NOTE

Summary of Contents for SHLD 2

Page 1: ...Operating Instructions SHLD 2 Source Holder Document ID 63138 Radiometric...

Page 2: ......

Page 8: ...6 63138 US 200110 NOTES...

Page 12: ...10 63138 US 200110 NOTES...

Page 26: ...24 63138 US 200110 NOTES...

Page 42: ...40 63138 US 200110 NOTES...

Page 56: ...54 63138 US 200110 NOTES...

Page 68: ...66 63138 US 200110 NOTES...

Page 78: ...76 63138 US 200110 9 2 Dimensions Figure 9 7 Source Holder SHLD 2 Standard Version...

Page 79: ...63138 US 200110 77 Figure 9 8 SHLD 2 Beam Angles Figure 9 9 SHLD 2 Height for Source Exchange...

Page 80: ...78 63138 US 200110 Figure 9 10 Source Holder SHLD 2 with Limit Switch...

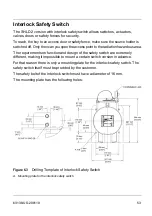

Page 81: ...63138 US 200110 79 Figure 9 11 Source Holder SHLD 2 with Interlock Safety Switch...

Page 82: ...80 63138 US 200110 Figure 9 12 Source Holder SHLD 2 with Air Actuator...

Page 83: ...63138 US 200110 81 Figure 9 13 Source Holder SHLD 2 with Air Actuator and Limit Switch...

Page 84: ...82 63138 US 200110 Figure 9 14 Source Holder SHLD 2 Explosion Proof with Limit Switch...

Page 86: ...84 63138 US 200110 NOTES...

Page 87: ......