52

63138-US-200110

1.

Open and remove padlock.

2.

The radiation safety officer gets a separate notification with the code for

the padlock. Contact your sales organization.

3.

Keep the padlock near by the source holder. Do not insert the padlock into

the opening of the "OFF" position or you cannot switch the source holder

off completely in case of emergency.

4.

Screw out safety screw (3) (screw is fixed to the safeguard cable and is

not detachable.

5.

Turn the operating lever 90° clockwise up to the stop. "ON" (1) then

appears in the position recess of the operating lever.

6.

Secure the operating lever in position "ON" (1).

7.

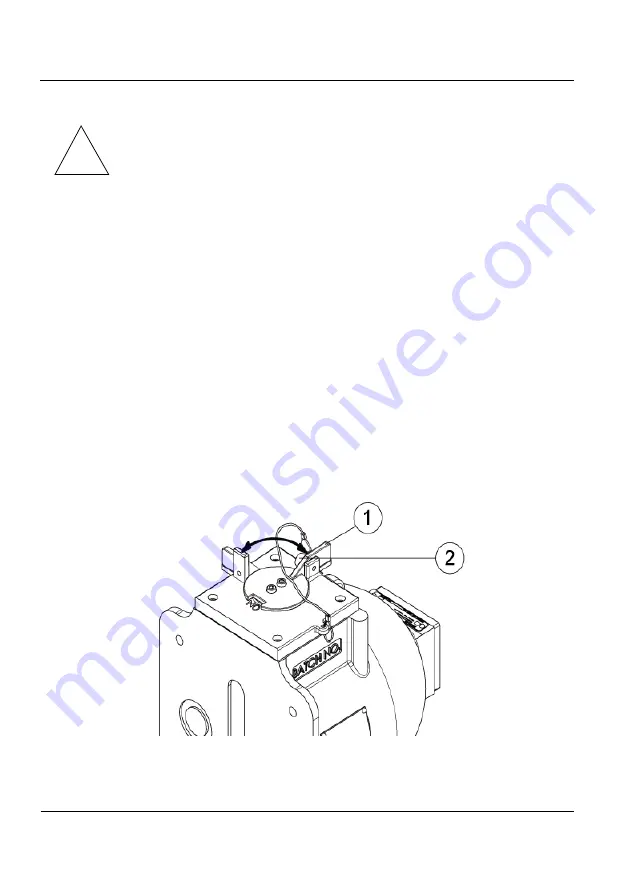

Screw in the safety screws (3) as shown in Figure 6.2. Vibrations or other

external influences can cause uncontrolled movement of the operating lever.

Figure 6.2

Safety Screws for Secure Switching Position

1. Operating lever in switching position "ON"

2. Safety screw

Make sure the source holder shutter is in the “OFF” position before

switching the radiation on.

!

NOTE

Summary of Contents for SHLD 2

Page 1: ...Operating Instructions SHLD 2 Source Holder Document ID 63138 Radiometric...

Page 2: ......

Page 8: ...6 63138 US 200110 NOTES...

Page 12: ...10 63138 US 200110 NOTES...

Page 26: ...24 63138 US 200110 NOTES...

Page 42: ...40 63138 US 200110 NOTES...

Page 56: ...54 63138 US 200110 NOTES...

Page 68: ...66 63138 US 200110 NOTES...

Page 78: ...76 63138 US 200110 9 2 Dimensions Figure 9 7 Source Holder SHLD 2 Standard Version...

Page 79: ...63138 US 200110 77 Figure 9 8 SHLD 2 Beam Angles Figure 9 9 SHLD 2 Height for Source Exchange...

Page 80: ...78 63138 US 200110 Figure 9 10 Source Holder SHLD 2 with Limit Switch...

Page 81: ...63138 US 200110 79 Figure 9 11 Source Holder SHLD 2 with Interlock Safety Switch...

Page 82: ...80 63138 US 200110 Figure 9 12 Source Holder SHLD 2 with Air Actuator...

Page 83: ...63138 US 200110 81 Figure 9 13 Source Holder SHLD 2 with Air Actuator and Limit Switch...

Page 84: ...82 63138 US 200110 Figure 9 14 Source Holder SHLD 2 Explosion Proof with Limit Switch...

Page 86: ...84 63138 US 200110 NOTES...

Page 87: ......