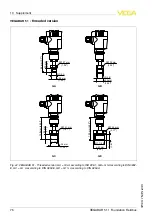

VEGABAR

51

-

C

apillary line with

fl

ange isolating diaphragm

4.53" 0.71"

0.71"

0.71"

0.55"

0.71"

0.71"

0.79"

0.79"

2.68"

5.91"

3.47"

6.5"

4.02"

DN

mm

PN

b

D

25

40

115

18

d4

68

40

40

150

18

88

50

40

165

20

102

d2

k

85

14

110

18

125

18

80

40

200

20

138

160

18

DN

inch

PN

b

D

25

40

40

40

50

40

d4

3.35"

4.33"

4.92"

7.87"

5.43"

80

40

6.3"

d2

1.77"

1.26"

2.32"

3.5"

Mb

32

45

59

89

Mb

k

b

ø d4

ø Mb

ø d2

ø k

ø D

ø 26 mm

(1.54")

30 mm

(1.81")

F

ig

.

42

:

VEGABAR

51

-

C

apillary line with

fl

ange isolating diaphragm

74

VEGABAR

51

•

F

oundation

F

ieldbus

10

S

upplement

36715

-

EN

-

110629