14

4 Mounting

VEGACAP 67 • Two-wire

31317-EN-200929

4.2 Mounting instructions

Due to the effects of agitators, equipment vibration or similar, the level

switch can be subjected to strong lateral forces. For this reason, do

not use an overly long electrode for VEGACAP 67, but check if you

can mount a short level switch on the side of the vessel in horizontal

position.

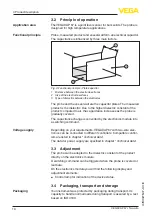

If the instrument is mounted in the filling stream, unwanted false

measurement signals can be generated. For this reason, mount the

instrument at a position in the vessel where no disturbances, e.g. from

filling openings, agitators, etc., can occur.

This applies particularly to instrument versions with a longer probe.

Fig. 5: Inflowing medium

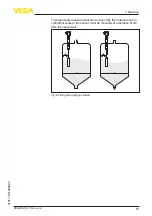

The probe should protrude into the vessel to avoid buildup. For that

reason, avoid using mounting bosses for flanges and screwed fittings.

This applies particularly to use with adhesive products.

In silos with bulk solids, material cones can form which change the

switching point. Please keep this in mind when installing the sensor

in the vessel. We recommend selecting an installation location where

the probe detects the average value of the material cone.

The probe must be mounted in a way that takes the arrangement of

the filling and emptying apertures into account.

Agitators and fluidization

Inflowing medium

Mounting socket

Material cone