22

7 Diagnostics and servicing

VEGACAP 98 • Relay (DPDT)

33760-EN-230510

7. Open the tensile ring on the old electronics module and pull out

the old electronics module.

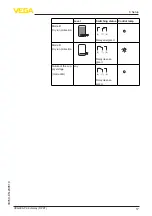

8. Compare the new electronics module with the old one. The type

label of the electronics module must correspond to that of the old

electronics module.

9. Insert the new electronics module.

10. Screw in and tighten the two screws with a Torx screwdriver.

11. Lead the connection cable through the cable gland.

12. Insert the wire ends into the open terminals according to the wir-

ing plan and tighten them.

13. Check the hold of the wires in the terminals by lightly pulling on

them.

14. Tighten cable gland and check on tightness. The seal ring must

completely encircle the cable.

15. Carry out a fresh adjustment. See chapter "

Set up, new adjust-

ment

".

16. Screw the housing lid back on

The electronics exchange is now finished.

7.4 How to proceed if a repair is necessary

You can find an instrument return form as well as detailed information

about the procedure in the download area of our homepage. By doing

this you help us carry out the repair quickly and without having to call

back for needed information.

Proceed as follows in case of repair:

•

Print and fill out one form per instrument

•

Clean the instrument and pack it damage-proof

•

Attach the completed form and, if need be, also a safety data

sheet outside on the packaging

•

Ask the agency serving you to get the address for the return ship-

ment. You can find the agency on our homepage.

Summary of Contents for VEGACAP 98

Page 11: ...11 4 Mounting VEGACAP 98 Relay DPDT 33760 EN 230510 Fig 4 Inflowing medium...

Page 28: ...28 Notes VEGACAP 98 Relay DPDT 33760 EN 230510...

Page 29: ...29 Notes VEGACAP 98 Relay DPDT 33760 EN 230510...

Page 30: ...30 Notes VEGACAP 98 Relay DPDT 33760 EN 230510...

Page 31: ...31 Notes VEGACAP 98 Relay DPDT 33760 EN 230510...