68

11 Supplement

VEGAPULS 65 • Foundation Fieldbus

36518-EN-140209

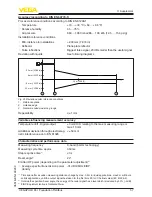

Fig. 40: Schematic presentation function block Arithmetic

Parameter list

The following table gives you an overview of the parameters used.

FF desciptor

Description

Unit

PRIMARY_VALUE

PRIMARY_VALUE (Linearized value). This is the process val

-

ue after min/max adjustment and Linearization with the status

of the transducer block. The unit is defined in "

PRIMARY_VAL-

UE_UNIT

"

PRIMARY_VALUE_UNIT

Selected unit code for "

PRIMARY_VALUE

"

SECONDARY_VALUE_1

This is the measured value after min/max adjustment with the

status of the transducer block. The unit is defined in "

SECOND

-

ARY_VALUE_1_UNIT

"

SECONDARY_VALUE_1_

UNIT

Selected unit code for "

SECONDARY_VALUE_1

"

SECONDARY_VALUE_2

This is the distance value ("

sensor_value

") with the status of the

transducer block. The unit is defined in "

SECONDARY_VAL

-

UE_2_UNIT

"

FILL_HEIGHT_VALUE

Filling height. The unit is defined in "

FILL_HEIGHT_VALUE_

UNIT

"

FILL_HEIGHT_VALUE_UNIT Filling height unit

CONST_VALUE

Constant value

SECONDARY_VALUE_1_

TYPE

Secondary value 1 type

SECONDARY_VALUE_2_

TYPE

Secondary value 2 type

FILL_HEIGHT_VALUE_Type

Filling height value type

DIAGNOSIS

AITB Diagnosis

DIAG_MASK_1

DIAG_OUT_1