64

9 Diagnosis, Asset Management and service

VEGAPULS SR 68 • 4 … 20 mA/HART two-wire

38294-EN-130624

Error

Cause

Rectification

4 … 20 mA signal

not stable

– Fluctuations of

the measured

variable

– Set damping according to the

instrument via the display and

adjustment module or PACTware/

DTM

4 … 20 mA signal

missing

– Electrical con-

nection faulty

– Check connection according to

chapter "

Connection steps

" and

if necessary, correct according to

chapter "

Wiring plan

"

– Voltage supply

missing

– Check cables for breaks; repair if

necessary

– Operating volt-

age too low or

load resistance

too high

– Check, adapt if necessary

Current sig-

nal greater than

22 mA or less

than 3.6 mA

– Electronics

module in the

sensor defec-

tive

– Exchange the instrument or send it

in for repair

The below tables show typical examples for application-relevant

measurement errors with bulk solids. There are two measurement

errors:

•

Constant level

•

Filling

•

Emptying

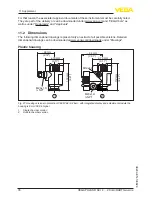

The images in column "

Error pattern

" show the real level with a bro-

ken line and the level displayed by the sensor as a continuous line.

1

2

Level

time

0

1 Real level

2 Level displayed by the sensor

Notes:

•

Wherever the sensor displays a constant value, the reason could

also be the fault setting of the current output to "Hold value"

•

In case of a too low level indication, the reason could be a line

resistance that is too high

Treatment of measure-

ment errors with bulk

solids