18

4 Mounting

VEGAPULS WL 61 • Profibus PA

38062-EN-140801

If large vessel installations such as struts or supports cause false

echoes, these can be attenuated through supplementary measures.

Small, inclined sheet metal baffles above the installations scatter the

radar signals and prevent direct interfering reflections.

Fig. 15: Cover smooth profiles with deflectors

Through the action of filling, stirring and other processes in the vessel,

compact foams that considerably damp the emitted signals may form

on the product surface.

If foams are causing measurement errors, the biggest possible radar

antennas, the electronics with increased sensitivity or low frequency

radar sensors (C band) should be used.

As an alternative, sensors with guided microwave can be used. These

are unaffected by foam generation and are best suited for such ap-

plications.

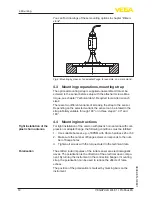

The short examples give you introductory information on the flow

measurement. Detailed planning information is available from flume

manufacturers and in special literature.

h

ma

x

d

mi

n

≥ 2 mm x h

ma

x

90°

4

3 ... 4 h

max

≥ 50 mm

90°

2

3

1

Fig. 16: Flow measurement with rectangular flume: d

min.

= min. distance of the

sensor (see chapter "Technical data"); h

max.

= max. filling of the rectangular

flume

1 Overflow orifice (side view)

2 Headwater

3 Tail water

4 Overfall orifice (view from bottom water)

In general, the following points must be observed:

•

Install the sensor on the headwater side

•

Installation in the centre of the flume and vertical to the liquid

surface

•

Distance to the overfall orifice

Foam generation

Flow measurement with

rectangular flume