35

9 Supplement

VEGAPULS WL 61 • Profibus PA

38062-EN-140801

Ʋ Air pressure

860 … 1060 mbar/86 … 106 kPa (12.5 … 15.4 psig)

Installation reference conditions

Ʋ Min. distance to installations

> 200 mm (7.874 in)

Ʋ Reflector

Plane plate reflector

Ʋ False reflections

Biggest false signal, 20 dB smaller than the useful signal

Deviation with liquids

See following diagrams

0,5 m (1.6 ft)

10 mm (0.394 in)

- 10 mm (- 0.394 in)

2 mm (0.079 in)

- 2 mm (- 0.079 in)

0

1

2

3

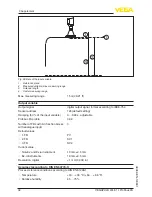

Fig. 36: Deviation under reference conditions

1 Reference plane

2 Antenna edge

3 Recommended measuring range

Repeatability

≤ ±1 mm

Variables influencing measurement accuracy

Temperature drift - Digital output

±3 mm/10 K relating to the max. measuring range or

max. 10 mm

Additional deviation through electromag-

netic interference acc. to EN 61326

< ±50 mm

Characteristics and performance data

Measuring frequency

K-band (26 GHz technology)

Measuring cycle time approx.

450 ms

Step response time

1)

≤ 3 s

Beam angle

2)

10°

Emitted HF power

3)

Ʋ Average spectral transmission power

density

-34 dBm/MHz EIRP

Ʋ Max. spectral transmission power

density

+6 dBm/50 MHz EIRP

Ʋ Max. power density in a distance of

1 m

< 1 µW/cm²

1)

Time span after a sudden distance change of max. 0.5 m until the output signal reaches for the first time 90% of

the final value (IEC 61298-2).

2)

Outside the specified beam angle, the energy of the radar signal has a level which is reduced by 50 % (-3 dB)

3)

EIRP: Equivalent Isotropic Radiated Power