29

6 Setup

VEGASWING 63 • Two-wire 8/16 mA

29232-EN-180704

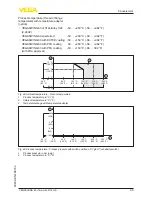

Note:

Keep in mind that the starting time t

A

of the voltage supply can extend

the time up to the first switching (e.g. VEGATOR 636: +1 s)

Test procedure

After releasing the button or after a brief line break.

Sensor

current -

Sensor

Level relay

A - overfill

protection

Signal lamp

A - Overfill

protection

Level relay

B - dry run

protection

Signal lamp

B - Dry run

protection

Fail safe

relay

Control

lamp

1. Fault sig-

nal

0.6 s

(±0,2 s)

+ t

A

1)

< 3.6 mA

currentless

currentless

currentless

2. Empty

signal

1.5 s

(±0.5 s)

8 mA

(±1.5 mA)

energized

currentless

energized

3. Full signal

1.5 s

(±0.5 s)

16 mA

(±1.5 mA)

currentless

energized

energized

4. Return

to current

operating

condition

-

-

-

-

-

-

Test assessment (SPLC)

Test passed

Status

Current value

Time

False signal

< 3.6 mA

0.6 s (±0.2 s)

Uncovered

8 mA (±1.5 mA)

1.5 s (±0.5 s)

Covered

16 mA (±1.5 mA) 1.5 s (±0.5 s)

This test is valid if you cannot change the vessel filling or cannot

dismount the sensor.

With the VEGATOR 121 or 122 signal conditioning instrument, the

test result can be checked directly on an LED on the signal condition-

ing instrument.

This is the most comfortable and simple way to carry out the test.

A test key is lowered in the front plate of the VEGATOR 121, 122

signal conditioning instrument. Push the test key for > 2 seconds with

a suitable object. Hence a test is started. The sensor must neither be

dismounted nor triggered by filling the vessel.

4 Test key on the signal

conditioning instrument

VEGATOR 121, 122

1)

Starting time of the voltage supply