31

7 Maintenance and fault rectification

VEGASWING 63 • Two-wire 8/16 mA

29232-EN-180704

7 Maintenance and fault rectification

7.1 Maintenance

If the device is used properly, no special maintenance is required in

normal operation.

7.2 Rectify faults

The operator of the system is responsible for taking suitable meas-

ures to rectify faults.

VEGASWING 63 offers maximum reliability. Nevertheless, faults can

occur during operation. These may be caused by the following, e.g.:

•

Sensor

•

Process

•

Voltage supply

•

Signal processing

The first measure to take is to check the output signal. In many cases,

the causes can be determined this way and the faults quickly rectified.

Should these measures not be successful, please call in urgent cases

the VEGA service hotline under the phone no.

+49 1805 858550

.

The hotline is manned 7 days a week round-the-clock. Since we offer

this service worldwide, the support is only available in the English

language. The service is free, only standard call charges are incurred.

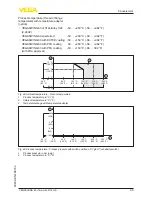

Error

Cause

Rectification

VEGASWING 63 signals

"covered" without being

submerged (overfill pro-

tection)

VEGASWING 63 signals

"uncovered" when being

submerged (dry run pro-

tection)

Operating voltage too low Check operating voltage

Electronics defective

Press the mode switch on the signal conditioning in-

strument. If the instrument then changes the mode, the

vibrating element may be covered with buildup or me-

chanically damaged. Should the switching function in

the correct mode still be faulty, return the instrument

for repair.

Press the mode switch on the signal conditioning in-

strument. If the instrument then does not change the

mode, the electronics module is defective. Exchange

the electronics module.

Unfavourable installation

location

Mount the instrument at a location in the vessel where

no dead zones or air bubbles can form.

Buildup on the vibrating el-

ement

Check the vibrating element and the sensor for buildup

and remove the buildup if there is any.

Wrong mode selected

Set the correct mode on the signal conditioning instru-

ment (overflow protection, dry run protection). Wiring

should be carried out according to the idle current prin-

ciple.

Reaction when malfunc-

tion occurs

Causes of malfunction

Fault rectification

24 hour service hotline

Checking the switching

signal