16

5 Connecting to power supply

VEGAVIB 61 • Two-wire 8/16 mA

29268-EN-170315

3. Remove approx. 10 cm (4 in) of the cable mantle, strip approx.

1 cm (0.4 in) of insulation from the ends of the individual wires

4. Insert the cable into the sensor through the cable entry

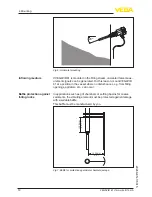

5. Lift the opening levers of the terminals with a screwdriver (see

following illustration)

Fig. 8: Connection steps 5 and 6

6. Insert the wire ends into the open terminals according to the wir-

ing plan

7. Press down the opening levers of the terminals, you will hear the

terminal spring closing

8. Check the hold of the wires in the terminals by lightly pulling on

them

9. Tighten the compression nut of the cable entry gland. The seal

ring must completely encircle the cable

10. If necessary, carry out a fresh adjustment

11. Screw the housing lid back on

The electrical connection is finished.

5.3 Wiring plan, single chamber housing

The following illustrations apply to the non-Ex as well as to the Ex-d

version.