SERVICE INFORMATION

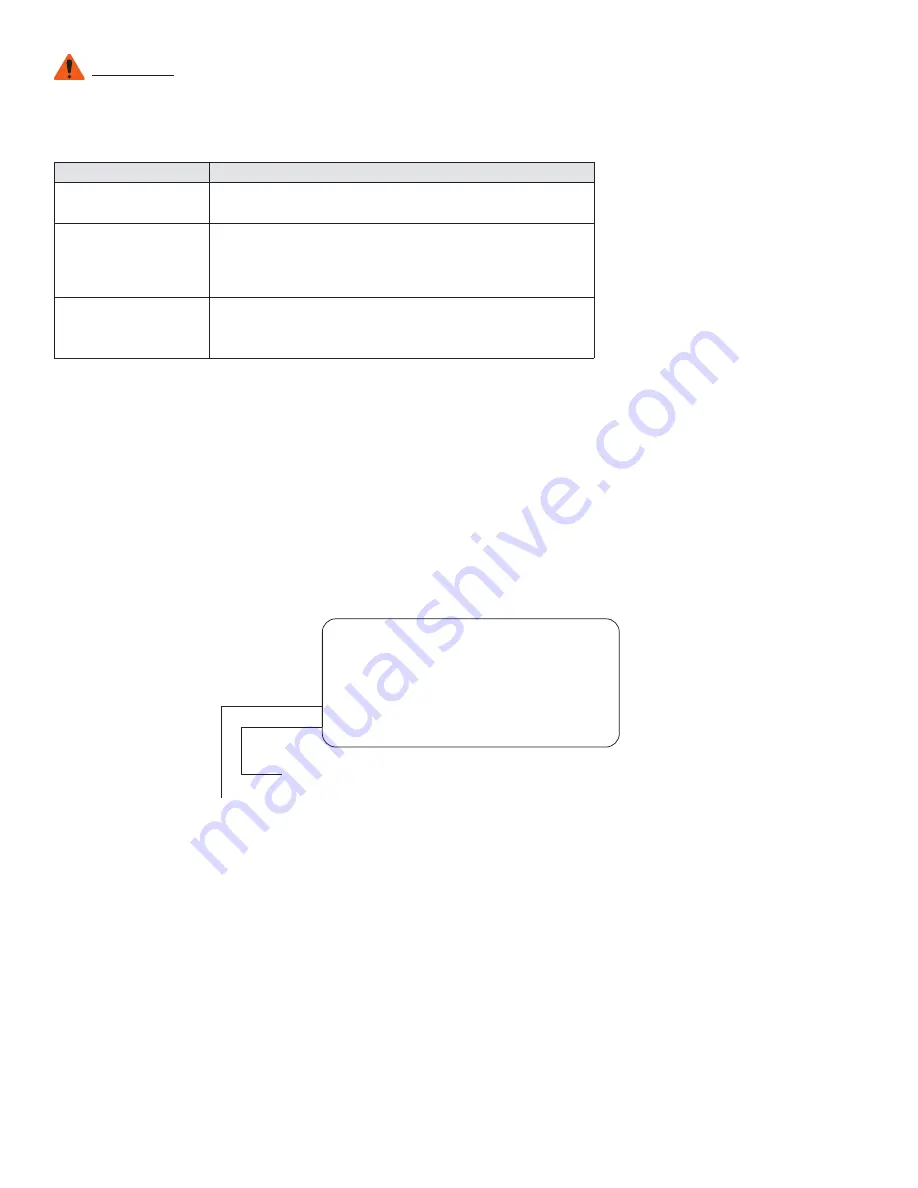

The following label has been attached to the packaging.

The “BZDxxxxx” marked on the label is Veigel’s part number of the hand control. It differs depending on the

specific installation kit. The type of hand control (Classic or Compact) is identified in the installation kit manual.

Please write down the serial number of your Veigel Hand Control installation here:

SERIAL NUMBER.: ______________________________

NOTE:

The serial number is important for any kind of query or

request

. Also state this number

when contacting Veigel.

Veigel GmbH + Co. KG 74653 Kunzelsau

..

Typ: HA Ausf:

Typzeichen:

Fabrik-Nr.:

5xxxxx-xxx

Artikel-Nr.:

BZD00005

Part Number

Serial Number

Type

The entry 50xxxx-xxx states the fabrication number in order to track the fabrication. The number consists of

the production batch and serial number.

9

NOTE:

It is strongly recommended that all of the above maintenance and any necessary repairs

should be done only by a NMEDA/QAP (National Mobility Equipment Dealers

Association/Quality Assurance Program) certified dealer using properly trained personnel.

WARNING:

The following maintenance should be done by your local mobility dealer. Do

not

attempt maintenance or repairs on your own.

SCHEDULED MAINTENANCE

Schedule:

Perform this Service

After the first 600

miles (1,000km):

• Check all screw joints - in particular, the joints to the

pedal arms

Every 6,000 - 9,000

miles (10,000 -

15,000 km):

• Grease joints and ball joints

• Reset and retighten all screw joints

• Check the adjustment of the linkage

Every 12,000 miles

(20,000 km) or in a

interval of a year:

All bearings (ball joints and slide bearing surfaces) have

to be lubricated with spray grease and all screws and

attachments have to be checked for tight fit.