3.1 Installation of Camera and Lens

Carefully read the instruction manual before installation to learn whether the CCD

specifications and interface forms of the lens and camera are consistent; the 1/3 or 1/2 inch

lens can be installed in the 1/3 inch CCD camera, and only the 1/2 inch lens can be installed

in the 1/2 inch CCD camera, otherwise, vignette may be generated on the picture edge.

Figure 4. Lens Installation

After the lens and camera are installed, adjust the back focal length of the camera, and then

observe the clear degree of test card on the monitor.

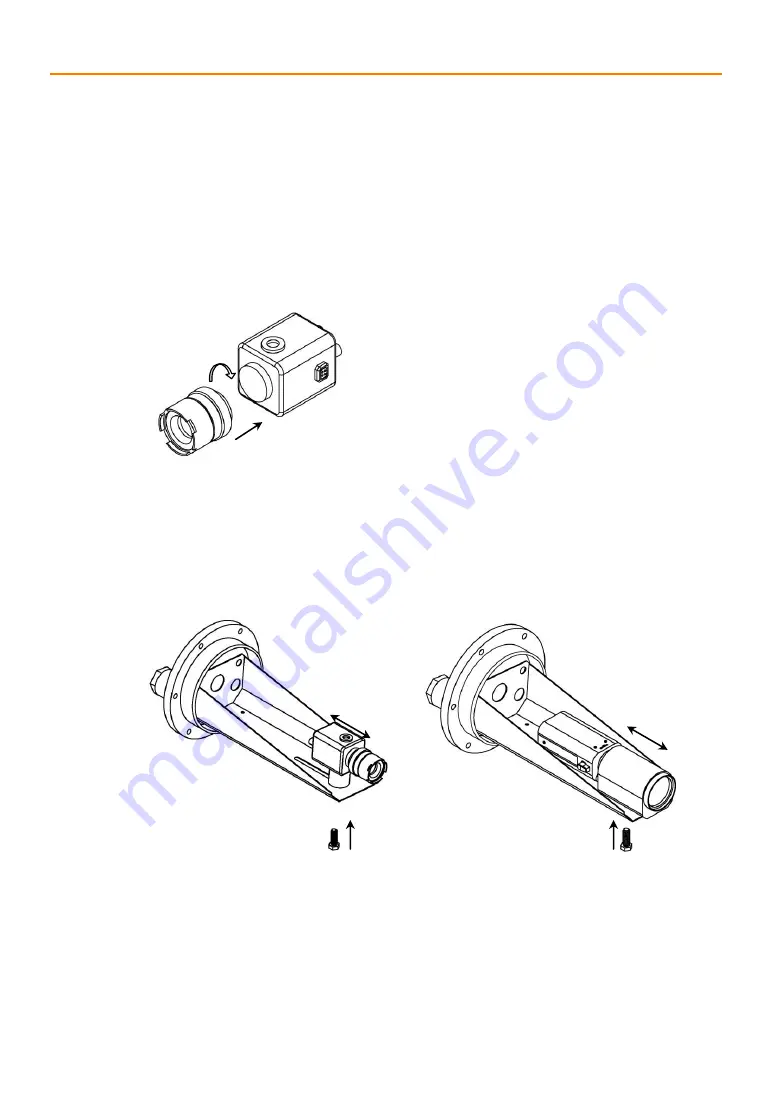

Install the properly debugged lens and camera on the drawer plate of the housing, and adjust

their front and rear positions to ensure that the picture edge has no vignette after the barrel is

mounted.

Figure 5. Installation of Camera and Prime Lens

Figure 6. Installation of Camera and Zoom Lens

on Drawer Plate

on Drawer Plate

Tighten after

insertion

SVEX

-T500A

SVEX

-T500A

Adjust the front

and rear

positions

Fasten with screw

Fasten with screw

Adjust the front

and rear

positions

SVEX

-T500A Explosion Proof Camera User Manual.

3- Installation

8