Installation

General instructions

33

cpg.1

Fully SF6 gas insulated single and double busbar GIS switchgears up to 36 kV in accordance

with IEC Standards

IG-137-EN version 03 ; 23/06/2016

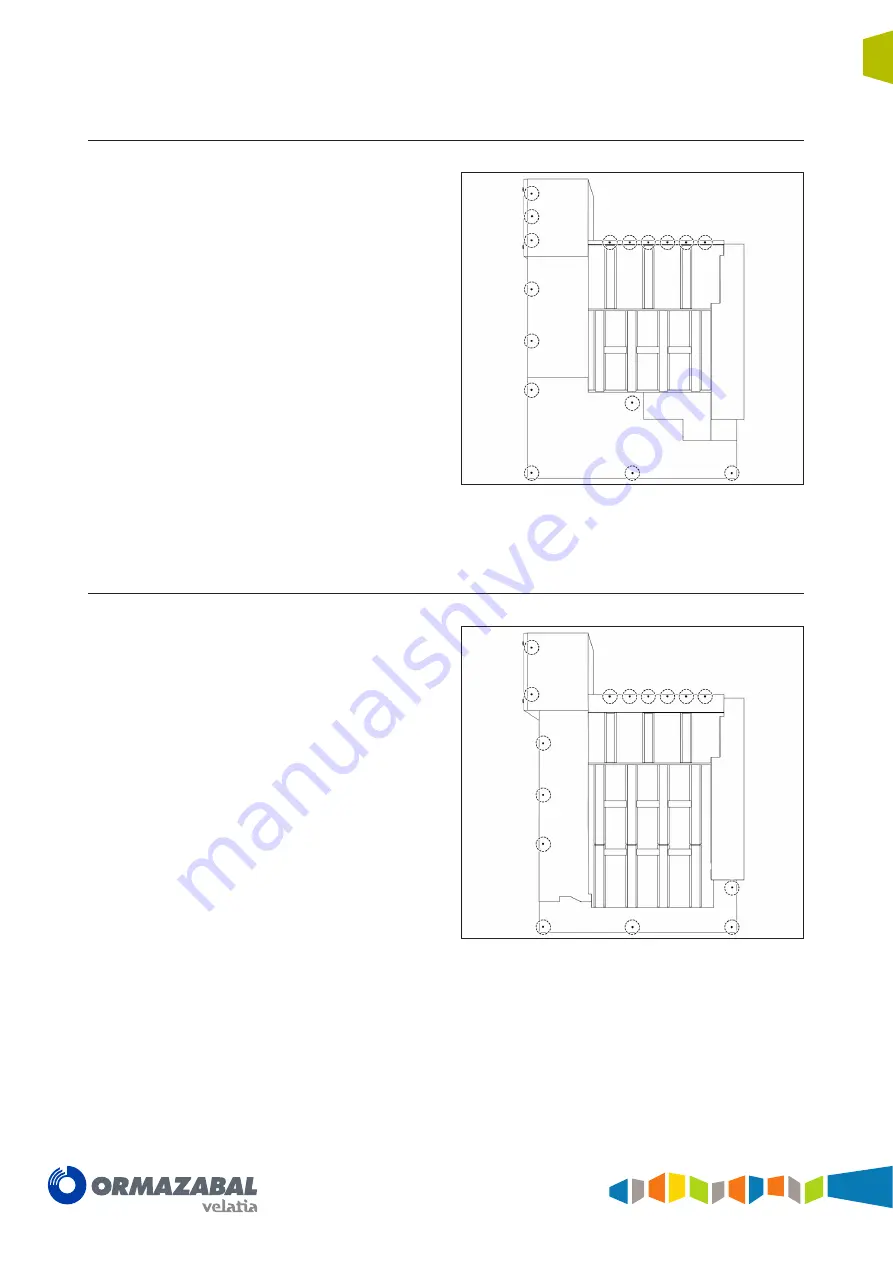

6.6.2

cpg.1-s

The fixing points for disconnector cubicles are defined in

Figure 6.10

:

Figure 6.10

Fastening points for the disconnector cubicle

6.6.3

cpg.1-ct / cpg.1-cl

The fixing points for busbar coupling cubicles are defined

in

Figure 6.11

:

Figure 6.11

Fastening points for transverse and longitudinal

busbar coupling cubicles

Summary of Contents for Ormazabal cpg.1 Series

Page 67: ......