ДЛИНА СТЕЖКА

STITCH LENGTH

The stitch length adjustment is made

according to kinds of sewing fabrics,

differential feed ratio etc.

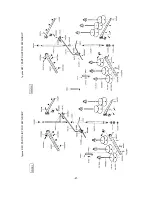

■ Keep pushing the Push Button(1)deep inside

and turn pulley for locking the Push Button

clutch and keep continuing to turn pulley to the

desired stitch length marking and then release

the Push Button. (Fig.14, Tab.2)

Длина стежка подбирается в зависимости от мате-

риала и величины необходимой дифференциальной

подачи.

■ Утопите кнопку (1) и поворачивайте маховое

колесо, до зацепления. Затем, удерживая кнопку

(1), выберите длину стежка в соответствии с

маркировкой на маховом колесе и отпустите

кнопку (1) (Рис.14, Таб.2)

РЕГУЛИРОВКА ДИФФЕРЕНЦИ-

АЛЬНОЙ ПОДАЧИ

DIFFERENTIAL FEED RATIO

ADJUSTMENT

Дифференциальная подача это соотношение

перемещения главного транспортера к перемеще-

нию дифференциального. Когда перемещение

главного транспортера больше чем дифференци-

ального, материал во время шитья будет растя-

гиватьсяog, если наоборот, то посаживаться.

■ Отпустите гайку (1) и установите рычаг регуля-

тора (2) выше или ниже;

При опускании вниз происходит увеличение

посадки материала, при поднимании -

растяжение. После окончания регулировки

The differential feed ratio is the ratio of

Main Feed Dog movement to Differential Feed Dog

movement. When the movement of Main Feed Dog

is bigger than Differential Feed Dog, the fabric will

be stretched in sewing, on the other hand the

fabric will be shrunk.

■ Loosen Nut (1) and press the

Adjusting Lever (2) upward or downward;

downward adjustment may cause stretching

effect. On the contrary, upward adjustment

may cause shrinking effect. When adjustment

is finished, tighten up Nut (1). (Fig.15, Tab.3)

Scale/Шкала

1

2

3

4

5

Diffe

re

nt

ia

l f

eed

ra

tio

/

Д

иффе

ре

нциа

л

1:1.3

-

1:0.7 1:0.9 1:1.1 1:1.3

1:2 1:0.7 1:1 1:1.14 1:1.17 1:2

1:3

1:1 1:1.5

1:2 1:2.5 1:3

1:4 1:1.1 1:1.6 1:2.3 1:2.8 1:3.3

Таб.3/Tab.3

Рис. 15/Fig.15

-8-

Summary of Contents for VO700S-3

Page 1: ...VO700S SUPER HIGH SPEED OVERLOCK SEWING MACHINE VO700S SERIES Operation Manual Parts Book...

Page 10: ...TABLE CUT OUT VO700 series For VO700 series 9...

Page 11: ...10 TABLE CUT OUT VO700DD series For VO700DD series...

Page 12: ...PARTS LIST...

Page 17: ...KM PARTS LIST FOR KM GROUP KN PARTS LIST FOR KN GROUP 16...

Page 21: ...KW PARTS LIST FOR KW GROUP KW PARTS LIST FOR KW GROUP 20...

Page 22: ...21 KW PARTS LIST FOR KW GROUP KW PARTS LIST FOR KW GROUP...

Page 23: ...22 KX PARTS LIST FOR KX GROUP KY PARTS LIST FOR KY GROUP...

Page 24: ...23 KZ PARTS LIST FOR KZ GROUP...