105

107774-02- 4/18

XIII. Operation

(continued)

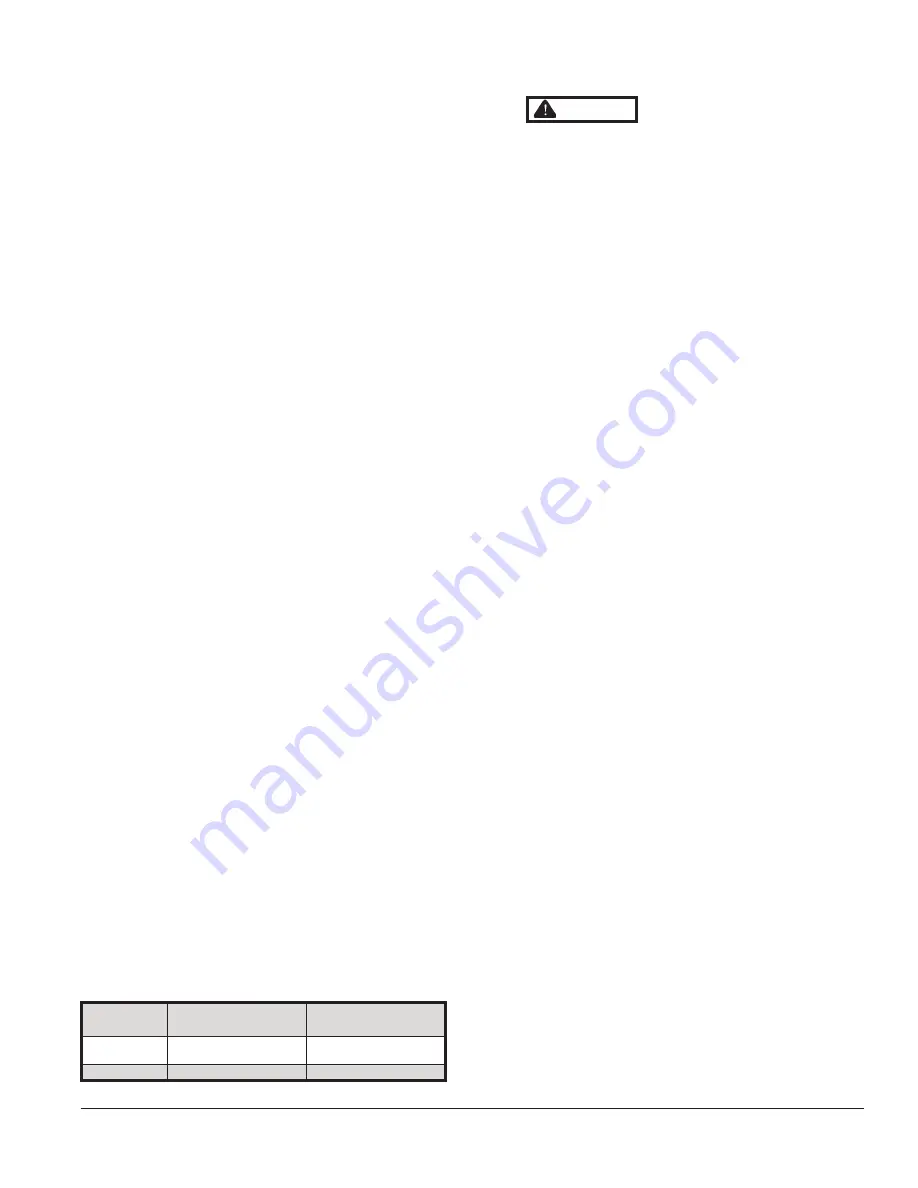

Table 13.2: Frost Protection

Device

Started

Start

Temperatures

Stop

Temperatures

Boiler Pump

Outside Air < 0°F (-18°C)

Supply Water < 45°F (7.2°C)

Outside Air > 4°F (-16°C)

Supply Water > 50°F (10°C)

Boiler

Supply Water < 38°F (3.3°C) Supply Water > 50°F (10°C)

D. Multiple Boiler Control Sequencer

This boiler may be used as a slave in a multiple

boiler system where the other boilers employ

the same control. Consult factory for additional

information on doing this.

4. External Limit

An external limit control can be installed on the

low voltage terminal strip. Be sure to remove the

jumper when adding an external limit control to

the system. If the external limit opens, the boiler

will shut down and an open limit indication and

error code are provided. If the limit installed is a

manual reset type, it will need to be reset before

the boiler will operate.

5. Boiler Mounted Limit Devices

The control monitors individual limit devices:

External Limit, Thermal Fuse, Sump Switch and

Boiler Water Flow Switch. If any of these limits

open the boiler will shut down and an open limit

indication is provided. Additionally, the control

monitors an air proving switch. During the boiler

start sequence the control requires the air proving

switch to be in the “open” position before the

blower starts and in the “closed” position after

the blower starts. If the air proving switch is not

in the required position the start sequence is

halted or the boiler is shut down and the open

limit indication is provided. The air proving switch

is only required to be closed during pre-purge.

It is normal for the air proving switch to be open

during run mode.

6. Stack High Limit

The Control monitors the flue gas temperature

sensor located in the vent connector. If the

flue temperature exceeds 194°F (90°C), the

control begins to reduce the maximum blower

speed. If the flue temperature exceeds 204°F

(96°C), a forced boiler recycle results. If the flue

temperature exceeds 214°F (101°C), the control

activates a manual reset Hard Lockout.

7. Ignition Failure

The Control monitors ignition using a burner

mounted flame sensor. In the event of an ignition

failure, the control retries 5 times and then goes

into soft lockout for one hour.

8. Central Heating System Frost Protection

When enabled, Frost Protection starts the boiler

and system pump and fires the boiler when low

outside air and low supply water temperatures

are sensed. The Control provides the following

control action when frost protection is enabled:

CAUTION The Control helps provide

freeze protection for the boiler water. Boiler

flue gas condensate drain is not protected from

freezing. Since the Control only controls the

system and boiler circulators individual zones

are not protected. It is recommended that

the boiler be installed in a location that is not

exposed to freezing temperatures.

Summary of Contents for K2WTC-135

Page 81: ...81 107774 02 4 18 X Domestic Hot Water Piping continued Figure 10 1 Domestic Hot Water Piping...

Page 89: ...89 107774 02 4 18 XI Wiring continued...

Page 90: ...90 107774 02 4 18 Figure 11 8 Internal Wiring Connections Diagram XI Wiring continued...

Page 101: ...101 107774 02 4 18 Lighting and Operating Instructions XII Start Up and Checkout continued...

Page 142: ...142 107774 02 4 18 XVI Repair Parts continued...

Page 145: ...145 107774 02 4 18 XVI Repair Parts continued...

Page 148: ...148 107774 02 4 18 XVI Repair Parts continued...

Page 150: ...150 107774 02 4 18 XVI Repair Parts continued...

Page 152: ...152 107774 02 4 18 XVI Repair Parts continued 120 121 122 123 124 125 126 127...

Page 159: ...159 107774 02 4 18 SERVICE RECORD DATE SERVICE PERFORMED...