51

107774-02- 4/18

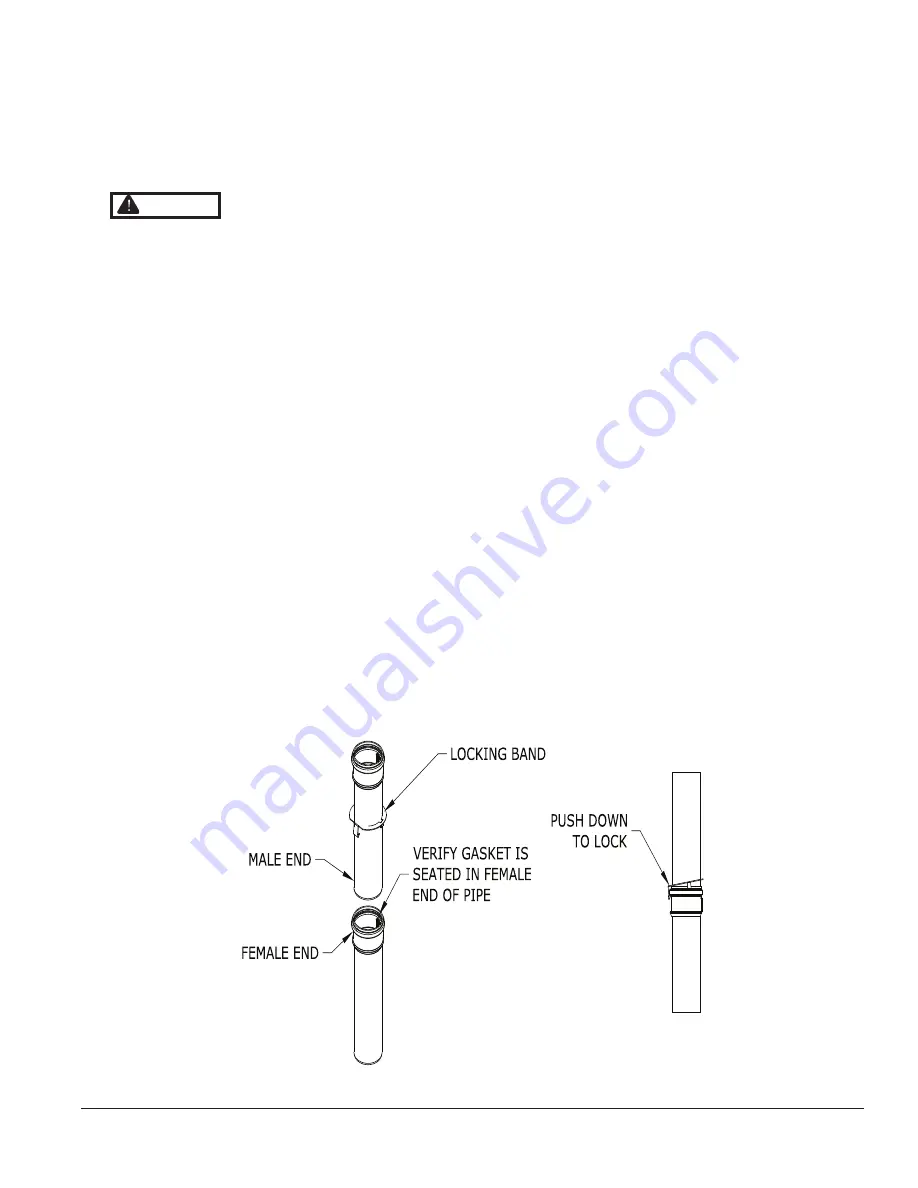

Figure 7.35: PolyPro Locking Band Installation

VII. Venting

F. Assembly of DuraVent PolyPro Vent Systems (continued

)

F. Assembly of DuraVent PolyPro Vent Systems

1. This boiler has been approved for use with the DuraVent PolyPro single wall Polypropylene vent system to be

provided by the installer.

2. Assemble the vent system, starting at the boiler:

a. The vent adaptor has three different inside diameters. The middle inside diameter accepts 3” nominal PolyPro

(Figure 7.27). A locking band clamp in the adaptor prevents the vent pipe from coming out of the adaptor

once it is installed and tightened. Lubricate the upper gasket in the vent adaptor with soapy water and insert

the first piece of 3” PolyPro into the adaptor until it bottoms out. Tighten locking band clamp to secure vent

pipe.

b. Assemble the next piece of 3” PolyPro.

c. For each joint, verify that the gasket is evenly seated in the bell (female) end of the pipe. Lubricate this gasket

with water. Slide a locking band over the male end of the pipe to be joined as shown in Figure 7.35. Push the

male end of the next section of pipe into the bell until it bottoms out, then back out 1/4-5/8” to provide room

for thermal expansion. Push barb on locking band over the bell end of the first section of pipe as shown in

Figure 7.35.

d. Assemble the rest of the vent system per the manufacturer’s installation instructions, being sure to pitch

horizontal sections back towards the boiler 5/8” per ft.

e. Support each horizontal pipe section with a minimum of one wall strap each and at intervals not exceeding

4ft.

WARNING Asphyxiation Hazard. Follow these instructions and the installation instructions included

by the original Polypropylene venting component manufacturers, M&G/DuraVent. Failure to do so could

cause products of combustion to enter the building, resulting in severe property damage, personal injury

or death. Where a conflict arises between M&G/DuraVent instructions and these instructions, the more

restrictive instructions shall govern.

Do not mix vent components or joining methods for listed manufacturers.

Examine all components for possible shipping damage prior to installation.

All condensate that forms in the vent must be able to drain back to the boiler.

Summary of Contents for K2WTC-135

Page 81: ...81 107774 02 4 18 X Domestic Hot Water Piping continued Figure 10 1 Domestic Hot Water Piping...

Page 89: ...89 107774 02 4 18 XI Wiring continued...

Page 90: ...90 107774 02 4 18 Figure 11 8 Internal Wiring Connections Diagram XI Wiring continued...

Page 101: ...101 107774 02 4 18 Lighting and Operating Instructions XII Start Up and Checkout continued...

Page 142: ...142 107774 02 4 18 XVI Repair Parts continued...

Page 145: ...145 107774 02 4 18 XVI Repair Parts continued...

Page 148: ...148 107774 02 4 18 XVI Repair Parts continued...

Page 150: ...150 107774 02 4 18 XVI Repair Parts continued...

Page 152: ...152 107774 02 4 18 XVI Repair Parts continued 120 121 122 123 124 125 126 127...

Page 159: ...159 107774 02 4 18 SERVICE RECORD DATE SERVICE PERFORMED...