29

110332-02 - 6/22

PHTM II

Installation, Operating & Service Instructions

9

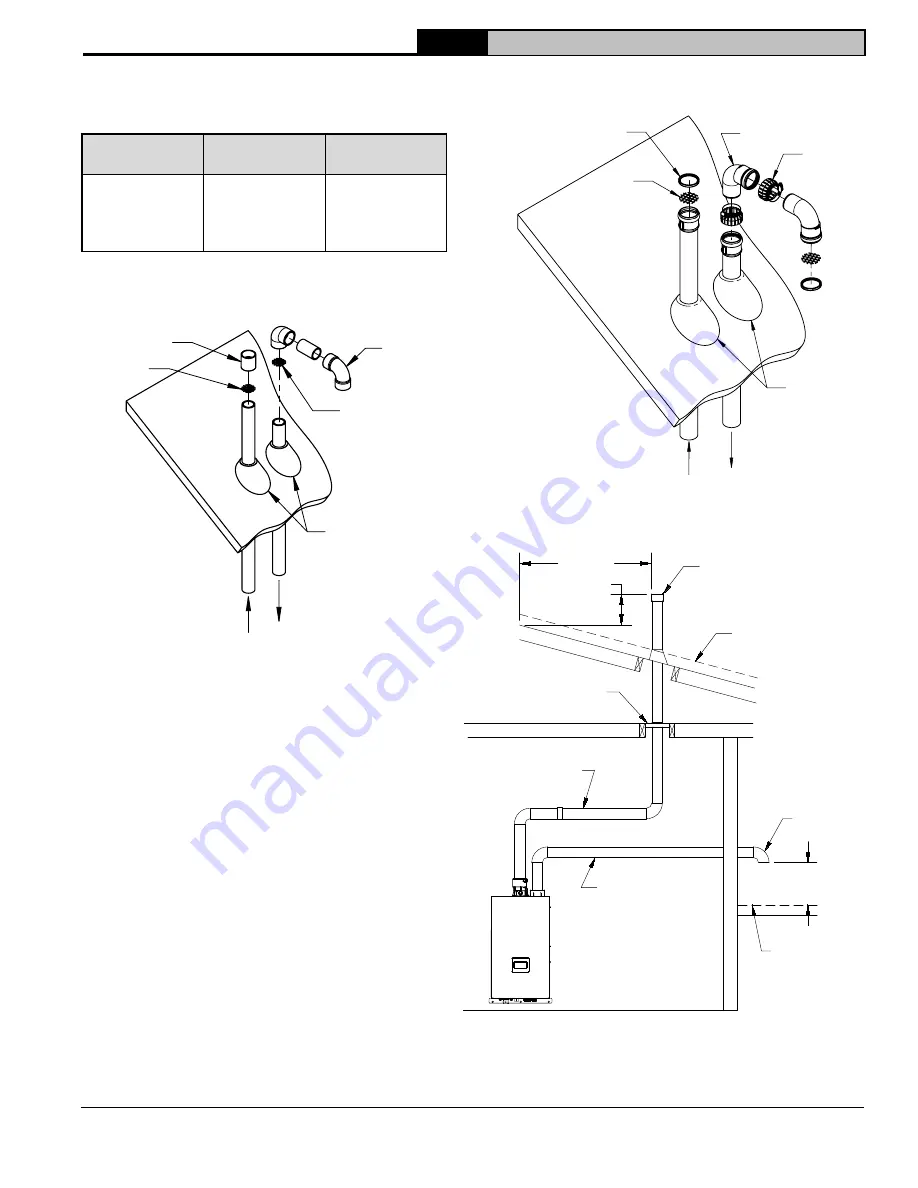

Vertical Direct Venting

(continued)

6. Assembly

A. Use appropriately sized roof flashing

to maintain proper clearance and

provide weather-tight seal.

B. If venting with polypropylene

i. Use UV resistant or UV stabilized

components for all exterior pipe and

fittings.

ii. Remove gasket from terminal fitting to

install screen.

7. Brace exterior vertical runs of piping as

required.

Figure 9-3: CPVC/PVC Fittings Terminal Assembly

Figure 9-4: Polypropylene Fittings Terminal

Assembly

Table 9-2: Polypropylene Vertical Terminal Fittings

DuraVent

PolyPro

Centrotherm

InnoFlue

Selkirk PolyFlue

UV resistant

single wall pipe

+ 2PPS-BG

screen

UV stabilized

end pipe +

IASPP02 screen

UV resistant

pipe + 2PF-

HVST screen

Figure 9-5: Alternate Vertical Vent/Sidewall Air

Terminal

Normal snow

line on roof

Elbow

with screen

Grade/Snow Line

10' (3.1m)

24" (610mm) Min

Air Intake Pipe

PVC Coupling or Polypropylene

end pipe with screen

Fire Stop listed for

use with vent system

Vent Pipe

Boiler

12" (305mm) Min

Roof Flashing

Elbow

Coupling

Screen

Screen

To boiler

air connection

From boiler

vent connection

Note: 2 in. (60 mm) components shown. Replace

"2" with "3" for 3 in. (80 mm) part numbers.

From boiler

vent connection

To boiler

air connection

Roof Flashing

DuraVent & Selkirk:

Remove gasket to

install screen

Screen

Elbow

Joint

Connector