37

110332-02 - 6/22

PHTM II

Installation, Operating & Service Instructions

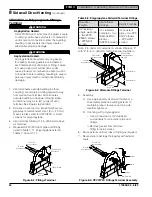

Tee & Plug

(Recommended for future

Heat Exchanger service)

Circulator

Drain Valve

Unions

Full Port Isolation Valves

From

System

Dirt & Magnetic Filter

(highly recommended)

A

B

Hydraulic Separator

may be substituted

for tees

Close Nipple

(locate Header Sensor

as close as possible

to downstream tee)

Air Separator

Expansion Tank

Fill Valve

Backflow

Preventer

Cold

Water

Line

Header Temperature

Sensor

(when used)

To

System

Flow Check

Valves

Optional Full Port

Isolation Valves

Heating

Circulators

Optional Full Port

Isolation Valves

To

System

A. At least eight pipe diameters upstream of first tee.

B. No further apart than 12" (305mm) (or four pipe diameters),

whichever is smaller.

System

Zone

Valves

Heating System

Circulator

Optional Zone Valve

Controlled System

REVISIONS

REV.

EN

DATE

DESCRIPTION

DWN

CHK

APVD

TITLE:

FIRST USE:

ITEM NUMBER:

MATERIAL:

ALTA

NEAR BOILER PIPING PRIMARY-SECONDARY

HEAT ONLY

DES: EJL

CHK:

APVD:

SCALE: 1:15

SIZE: B

SHEET: 1 OF 1

DATE:

REVISION:

DRAWING NUMBER:

09/09/2021

TS-103-65

A

UNLESS OTHERWISE NOTED: ALL DIMENSIONS IN INCHES.

TOLERANCES:

X.X ±.1 X.XXX ±.005 X.XX ±.03 ANGLE ±1°

PROPERTY OF

U.S. Boiler Company, Inc.

LANCASTER, PA

THIRD ANGLE PROJECTION

THIS DOCUMENT CONTAINS CONFIDENTIAL INFORMATION AND ITS CONTENTS ARE THE SOLE PROPERTY OF U.S. BOILER COMPANY, INC. ANY REPRODUCTION IN PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF U.S. BOILER COMPANY, INC. IS STRICTLY PROHIBITED.

A

A

B

B

4

4

3

3

2

2

1

1

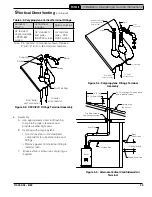

10

Heating System Piping

(continued)

NO

TICE

: Installer is r

esponsible for piping configurations to pr

ovide pr

oper flow rates and

meet local codes.

NO

TICE

: Primar

y-secondar

y piping is r

equir

ed.

C

A

UTION

Bur

n

Hazar

d.

P

roper

ty

Dama

g

e.

Under some conditions this boiler can deliver water to heating system that is significantly higher than boiler setpoint. Wher

e such overheat could cause personal injur

y or pr

oper

ty

damage (e.g. low temperatur

e radiant floor zones), pr

otect system fr

om excessive

temperatur

es using tempering valves or other means.

!

Figur

e 1

0-3:

Heating S

yst

em Piping