63

110332-02 - 6/22

PHTM II

Installation, Operating & Service Instructions

Boiler Protection Features

1. Supply Water Temperature High Limit

Control is equipped with internal operating

control and high limit features. Control monitors

a dual element temperature sensor that is UL353

and UL1998 listed. If supply water temperature

increases above the active setpoint plus diff

above, (default 190°F [87.7°C]) boiler is cycled

off. If temperature exceeds 210°F (98.9°C), a

manual reset hard lockout results. If boiler is

responding to internal Multiple Boiler Control

Sequencer, Header Sensor or an External EMS

demand and supply water temperature increases

above 190°F (87.7°C) control begins to reduce

the blower maximum speed setting and if the

temperature increases to 200°F (93°C) a forced

recycle results.

15

Operation

(continued)

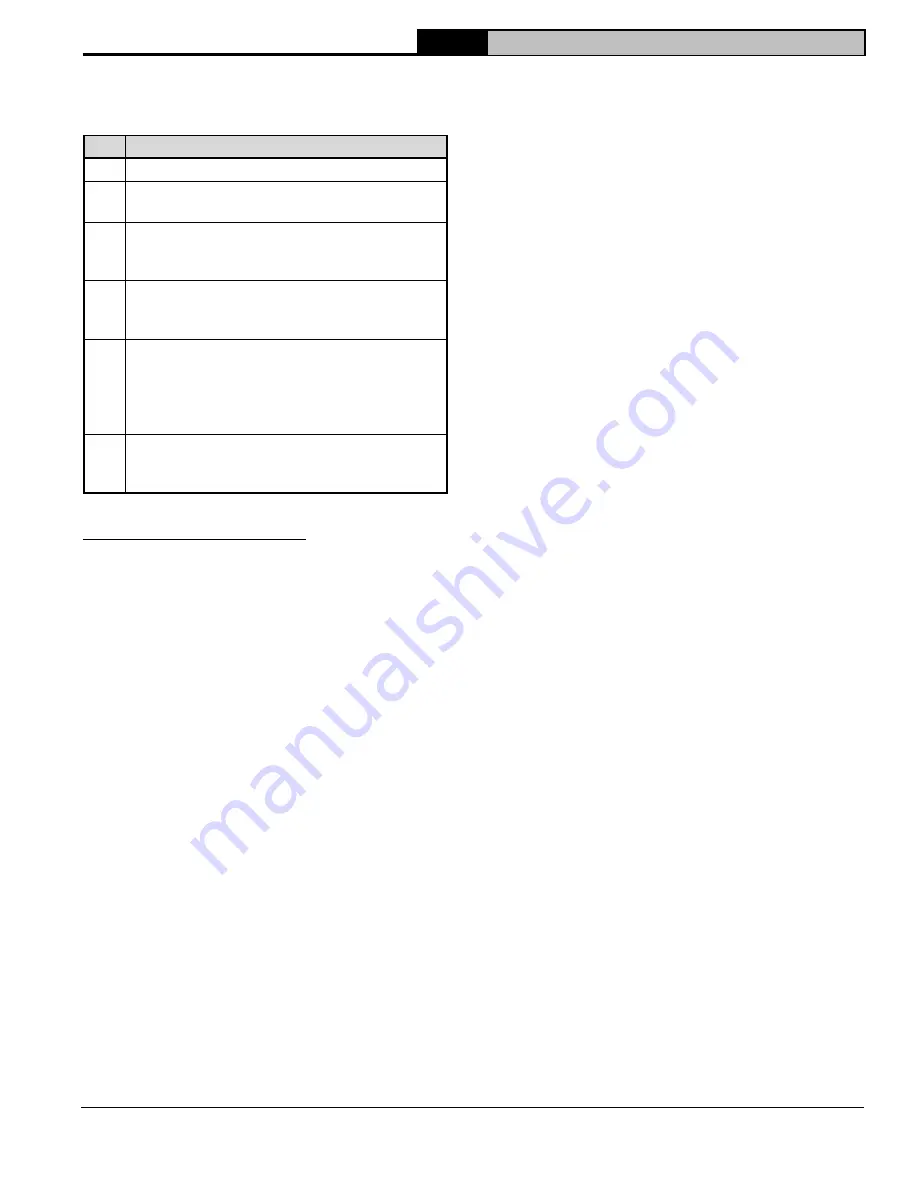

Table 15-18: Order of Priority

CO2

Boiler Responding to:

1st Domestic Hot Water

2nd Sequencer Control

Connected to the peer-to-peer network.

3rd Central Heat 1

CH1 call for heat is on and there is no DHW

demand or DHW priority time has expired.

4th Central Heat 2

CH2 call for heat is on and there is no Central

Heat 1 or DHW demand.

5th Frost Protection

Frost Protection is active and there is no

other call for heat. Frost protection will be a

higher priority than Sequencer Control if the

Sequence Master has no active call for heat.

6th Boiler Switch "On/Off"

When Boiler Switch is set to "Off" position the

boiler does not respond to any demands.

2. High Differential Temperature Limit

Control monitors temperature difference between

return and supply sensors. If this difference

exceeds 58°F (32°C) control begins to reduce

blower maximum speed and if temperature

difference exceeds 63°F (35°C) a forced boiler

recycle results. Boiler will restart automatically

once temperature difference has decreased and

minimum off time has expired.

3. Return Temperature Higher Than Supply

Temperature (inversion Limit)

Control monitors supply and return temperature

sensors. If return water temperature > supply

water temperature for longer than a limit time

delay control shuts down and restarts boiler and

delays. If inverted temperature is detected more

than five times, boiler manual reset Hard Lockout

is activated.

4. External High Limit

An external limit control can be installed on low

voltage connections terminal strip. Be sure to

remove jumper when adding an external limit

control to system. If external limit opens, the boiler

will shut down and an open limit indication and

error code is provided. If limit installed is a manual

reset type, it will need to be reset before boiler will

operate.

5. External (LWCO)

An external LWCO control (optional) can be

installed on the low voltage connections terminal

strip 24 VAC LWCO connection. If the LWCO

opens, boiler will shut down and an open limit

indiction and error code is provided. If LWCO

installed is a manual reset type, it will need to be

reset before boiler will operate.

6. Boiler Mounted Limit Devices

Control monitors thermal fuse (top of heat

exchanger) and boiler water flow switch. If either

of these limits open while the boiler is running,

boiler will shut down and a fault indication is

provided. Additionally, control monitors an air

pressure switch. During boiler start sequence,

control requires the air pressure switch to be

in "open" position before blower starts and in

"closed" position after blower starts. If this does

not happen, start sequence is halted and fault

indication is provided. Air pressure switch is

only required to be closed during pre-purge. It

is normal for the air proving switch to be open

during run mode.