22

PHTM II

Combi Installation, Operating & Service Instructions

110331-03 - 1/22

7

General Venting

(continued)

Polypropylene Venting

WARNING

Asphyxiation Hazard.

• Use only vent materials listed in Table 7-16

to make vent connections. Consult vent

manufacturer's instructions for required support

and special connections.

• Follow vent manufacturer's instructions

supplied with vent system.

• Do not mix vent systems of different types or

manufacturers.

• Maintain clearances to vent piping per Figure

5-1.

• Failure to comply with venting instructions

could cause products of combustion and/or

carbon monoxide to enter the building, resulting

in severe personal injury, death or substantial

property damage.

!

NOTICE:

Polypropylene vent connections

must be secured by vent manufacturer's joint

connector.

1. Slope polypropylene vent pipe not less than

5/8 in. per ft. (52 mm per m) upwards from

boiler to vent terminal for condensate drainage.

2. Support polypropylene venting per vent

manufacturer's instructions.

3. Examine all components for possible shipping

damage prior to installation.

WARNING

Asphyxiation Hazard.

All polypropylene vent systems rely on gaskets

for sealing. Ensure gaskets are installed in

each female end of vent pipe or fitting. Failure

to make proper joint connections could

cause products of combustion and/or carbon

monoxide to enter the building, resulting in

severe personal injury, death or substantial

property damage.

!

4. Work from boiler towards vent or air

termination. Do not exceed maximum

equivalent lengths shown in Table 7-7.

See Table 7-9 for equivalent lengths of elbows

and fittings.

5. Only cut polypropylene vent pipe as permitted

by vent manufacturer and in accordance with

their instructions. Ensure cut end is square and

deburred prior to assembly.

6. Boiler vent connector is gasketed. Lubricate

gasket with soapy water, insert pipe until it

bottoms out, and tighten clamp. See Figure

7-18.

7. Assemble remainder of vent system in

accordance with vent manufacturer's instruction

being sure to provide for thermal expansion.

Clamp sections together as directed by vent

manufacturer.

8. All air piping may be PVC or polypropylene.

PVC to polypropylene adapter required at boiler

connection if using polypropylene air piping.

9. Vent and air can be up-sized to 3 in. for

longer runs. Requires 2 x 3 in. polypropylene

increaser. Vent increaser must be directly

attached to boiler vent connector and must

be installed in vertical section of pipe. If using

polypropylene air piping, increaser must be

directly attached to PVC to polypropylene adapter

and must be installed in vertical section of pipe.

See Figure 7-19.

10. If using flexible polypropylene:

A. Maximum length of corrugated flexible

venting will be reduced vs. rigid pipe

due to higher pressure drop of flexible

venting. See Table 7-10.

B. Store vent material in ambient space 41°F

(5°C) or warmer before beginning installation.

Observe vent manufacturer's instructions for

storing and handling this pipe.

C. Use only in vertical or near vertical

installations with bends no greater than 45°.

Maximum two offsets (four bends).

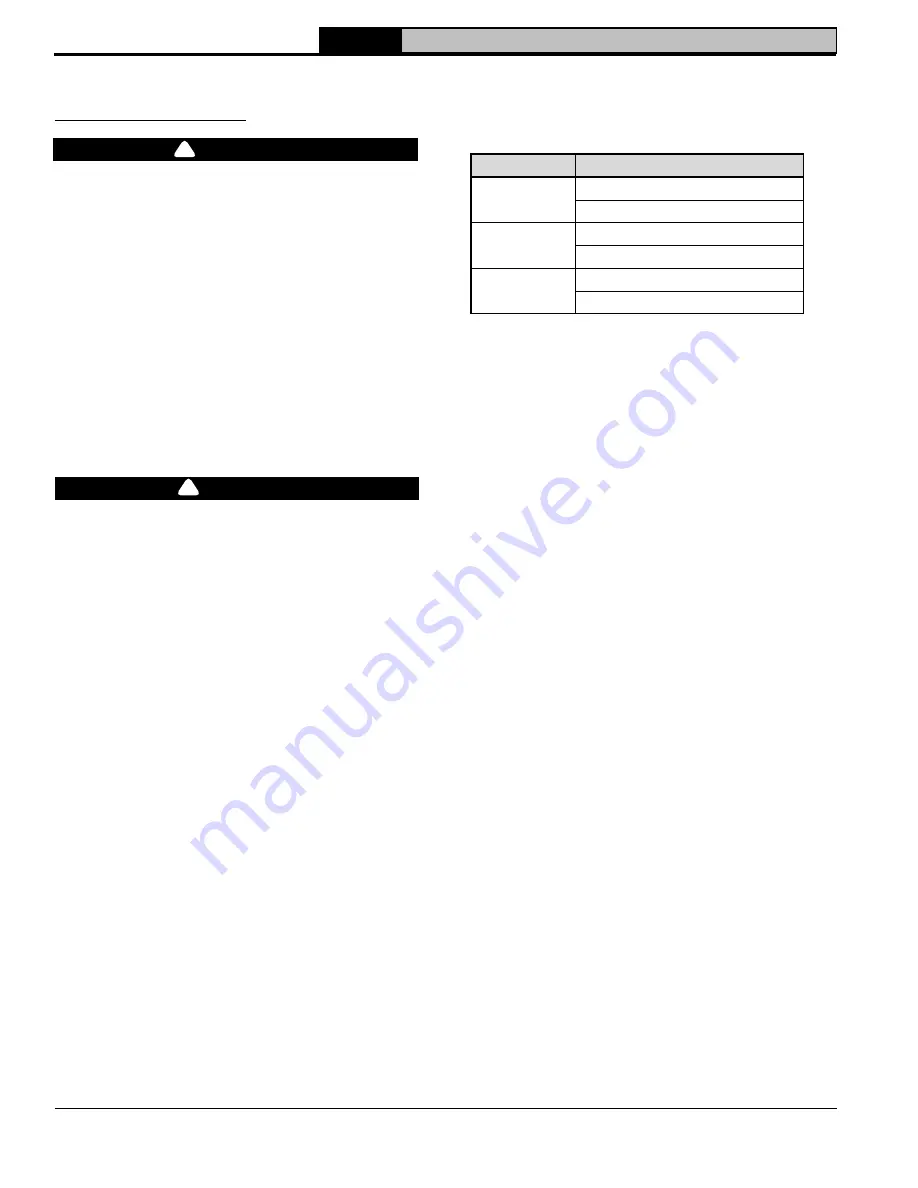

Manufacturer Model

DuraVent

Polypropylene Single Wall Rigid

PolyPro Flex

Centrotherm

InnoFlue Single Wall Rigid

InnoFlue Flex

Selkirk

PolyFlue Single Wall Rigid

PolyFlue Single Wall Flex

Table 7-16: Listed Polypropylene Vent Materials

(ULC-S636 Listed)