39

110331-03 - 1/22

PHTM II

Combi Installation, Operating & Service Instructions

11

Domestic Water Piping

NOTICE:

DHW feature on this boiler is designed

to only heat potable water (i.e. water from a well

or water utility that is suitable for drinking) having

following characteristics:

•

Hardness less than 12 grains/gallons

•

pH between 6 and 8

•

Chlorides less than 80 PPM

Use of water not having these characteristics

could result in premature failure of DHW handling

components in this boiler and is not covered

under warranty. If there is reason to believe water

is contaminated in any way, discontinue use

of domestic hot water and contact a qualified,

licensed water treatment professional.

DANGER

Scald Hazard.

• Under certain conditions this boiler

can deliver domestic hot water (DHW) at

temperatures in excess of DHW set point on

boiler control. A field supplied ASSE 1017 or

ASSE 1070 certified tempering valve is therefore

REQUIRED

as part of this boiler's installation.

• Select and install tempering valve in

accordance with valve manufacturer's

instructions and applicable local codes. In

absence of such codes follow Uniform Plumbing

Code (IAPMO/UPC-1). Also note additional

tempering valves may be required at fixtures

themselves.

!

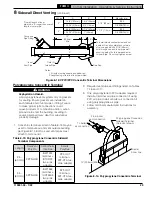

Combi connections are G1/2". Adapters to 3/4" sweat

connection are provided in parts carton (Figure 11-1).

DHW components in this system and their functions are

as follows:

1. ASSE 1070 or ASSE 1017 listed tempering

valve (required)

Low draw rates and transitions from heating to DHW

are two examples of conditions that can cause

temperature of water leaving boiler to significantly

exceed DHW set point. A tempering valve is

required to minimize spikes in DHW temperature.

Select and install in accordance with valve

manufacturer's instructions and applicable codes.

2. Flow limiter

If DHW draw rate is in excess of rating in Table

3-1, temperature of hot water may be too low for

comfortable use. Internal, 6 GPM (23 L/min), flow

limiter is factory installed, but an additional flow

limiter may be required. Select one having a flow

rating approximately equal to that shown in Table 3-1

at desired temperature rise.

3. DHW pressure relief valve

Limits pressure in DHW piping. Use a valve

designed for DHW service such as Watts #3L

or #53L. Select a valve with a pressure setting

less than or equal to 145 psig (1,000 kPa). Pipe

discharge to safe location using same size as

discharge connection to valve.

4. Drain valve

Permits plate heat exchanger to be periodically

back flushed to remove sediment.

5. Globe or ball valves

Used to isolate DHW piping during back flushing

and other servicing. In addition, valve may be used

to limit DHW flow if necessary.

6. Expansion tank

If back flow preventer or check valve is installed

upstream of cold connection, thermal expansion

tank will prevent build-up of pressure in DHW piping.

Use an expansion tank designed for potable water

service.

7. Water filter (highly recommended)

Install Aqua Pure AP430SS or equivalent on potable

cold water supply to prevent scale.

8. Buffer tank (Optional)

When recirculation line is installed as shown in Figure

11-3, a small (2-6 gal) potable water storage tank

may be installed as shown. Reduces burner cycling

during very small DHW demands and also helps

minimize temperature fluctuations. An unpowered

storage electric water heater is ideal for this

application.

Gasket

Gasket

DHW Connector

(Fits 3/4" Female Socket Elbow)

Figure 11-1: DHW Connections

CAUTION

Component Damage.

•

Internal components near Hot and Cold

connections can be damaged by excessive

heat during soldering. Use precautions to limit

heat exposure.

• Failure to do so could cause internal leaks

resulting in damage to boiler.

!

NOTICE:

Elbows pointed toward back of boiler

are recommended to start DHW piping.