120

106309-03 - 4/19

XII. Troubleshooting

(continued)

Lockout Number

Condition

Possible Cause

3

Burner Interlock Open (ILK OFF)

ILK safety limit input not energized

Lockout input (ILK) is not ON. Refer to Limit String Status screen for

list of limits.

• Man Reset Ext. Limit device open or jumper not installed

• High or low gas pressure switch open or jumper not installed

• Thermal link open

• Burner door thermostat open

• Loose or defective limit string wiring

4

Supply high limit

R7910 supply sensor detected

temperatures in excess of 210°F.

• Heating load at time of error was far below the minimum firing

rate of the boiler.

• Defective system circulator or no flow in primary loop.

• Defective boiler circulator, no flow or insufficient flow in boiler loop.

• Control system miswired so that the boiler operation is

permitted when no zones are calling.

6

Stack High limit

R7910 Flue gas (Stack) sensor detected

temperatures in excess of 204°F (95.6°C).

• Heat exchanger needs to be cleaned.

• Boiler over-fired.

• Air-fuel mixture out of adjustment - consult factory.

12

Flame detected out of sequence

A flame signal was present when there

should be no flame.

• Defective gas valve - make sure inlet pressure is below

maximum on rating plate before replacing valve.

14

Delta T Inlet/Outlet High

Temperature rise between supply and

return is too high.

Inadequate boiler water flow.

• Boiler pump not operating

• Boiler pump undersized

• Valve closed

15

Return Temperature

Higher Than Supply

Return temperature was greater than

supply temperature for at least 75

seconds.

• Reversed flow through boiler. Verify correct piping and circulator

orientation.

• No boiler water flow. Verify system is purged of air and

appropriate

valves are open.

• Defective supply or return sensor

16

Supply Temperature Risen Too

Quickly

Supply water temperature has risen too

quickly.

• Inadequate boiler water flow. See also causes for Hard Lockout 4.

• Boiler pump not operating

• Boiler pump undersized

• Valve closed

18

Light off rate proving failed

Blower is not running at Light-off rate

when it should or blower speed signal not

being detected by R7910.

• Loose connection in 120 VAC blower wiring.

• Loose or miswired blower speed harness.

• Defective blower

19

Purge rate proving failed

Blower is not running at Purge rate when

it should or blower speed signal not being

detected by R7910.

• Loose connection in 120 VAC blower wiring.

• Loose or miswired blower speed harness.

• Defective blower

20

Invalid Safety Parameters

Unacceptable R7910 control Safety

related parameter detected.

Parameters change was invalid. Check parameter selection and reset

Control. Contact factory if problem persists.

21

Invalid Modulation Parameter

Unacceptable R7910 control Modulation

related parameter detected.

Reset the control.

22

Safety data verification needed

Safety related parameter change has

been detected and a verification has not

been completed.

Safety related R7910 control parameter has been changed and verifi

-

cation has not been performed.

23

24VAC voltage low/high

R7910 control 24Vac control power is high

or low.

• Loose connection in 24Vac VAC power wiring.

• Loose or miswired 24Vac harness.

• Miswired wiring harness causing power supply short to

ground.

• Defective transformer.

• Transformer frequency, voltage and VA do not meet

specifications.

Hard Lockout Codes Displayed

G. Troubleshooting problems where a Hard Lockout Code is displayed.

When a hard lockout occurs, the

boiler will shut down, the display will turn red and the “Help” button will “blink”. Select the “blinking” “Help” button to

determine the cause of the Hard Lockout. Once the condition that caused the lockout is corrected, the boiler will need to be

manually reset using the Reset button on the “Active Fault” display or located on the R7910 Control.

Alarm Output Contact

The Control includes an alarm output contact located on Control terminals J6 - 7 & 8. The alarm contact closes when the

Control goes into a manual reset Hard Lockout. The list of Hard Lockouts is shown below.

Summary of Contents for Phantom-X PHNTM399C

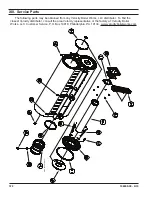

Page 49: ...49 106309 03 4 19 VI Water Piping and Trim continued Figure 28 Near Boiler Piping Heating Only...

Page 63: ...63 106309 03 4 19 VIII Electrical continued Figure 40 Ladder Diagram...

Page 64: ...64 106309 03 4 19 VIII Electrical continued Figure 41 Wiring Connections Diagram 2...

Page 73: ...73 106309 03 4 19 IX System Start up continued Figure 47 Operating Instructions...

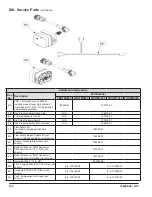

Page 124: ...124 106309 03 4 19 XIII Service Parts continued...

Page 130: ...130 106309 03 4 19 XIII Service Parts continued...

Page 133: ...133 106309 03 4 19 XIII Service Parts continued 10A 10B 10C 10D 10G...

Page 139: ...139 106309 03 4 19...