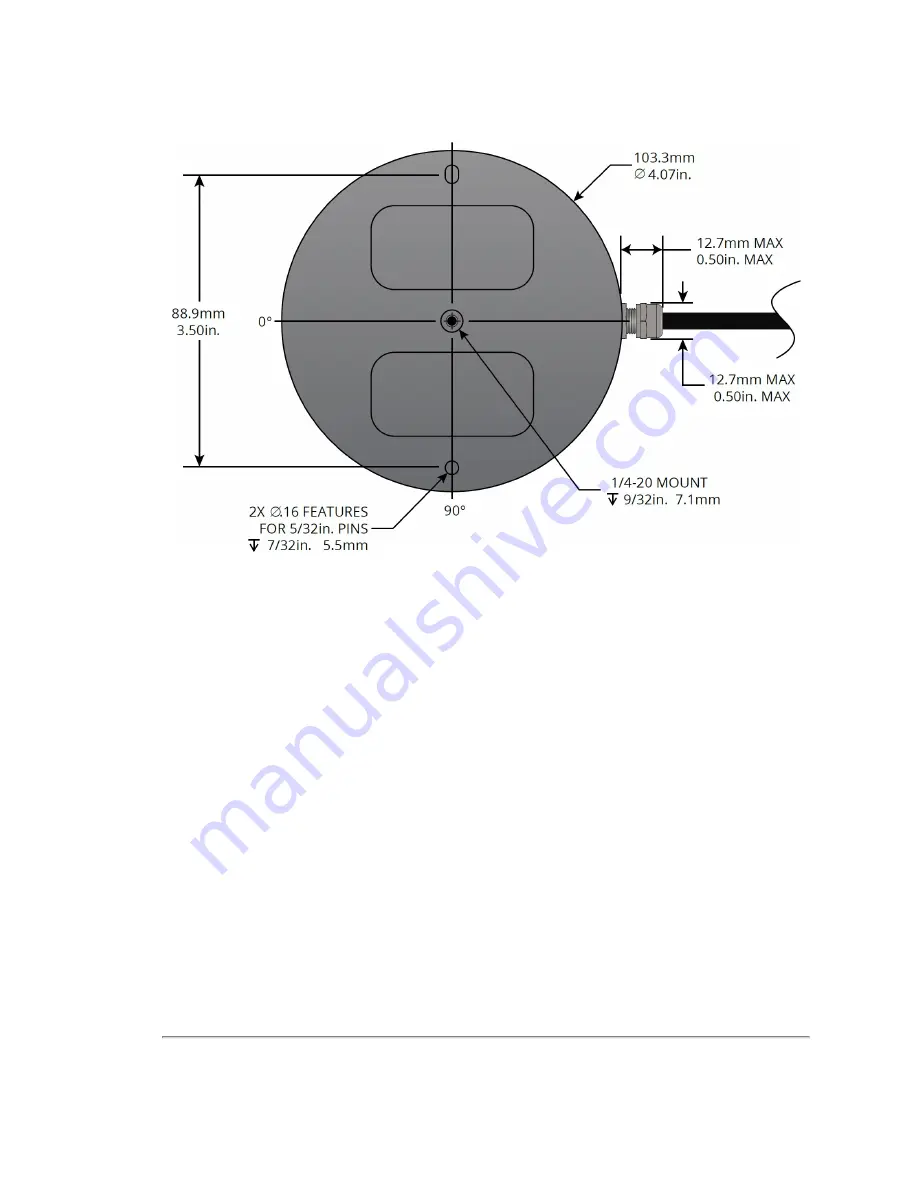

Figure 5-1 Mounting Details

5.3 Encapsulation, Solar Hats, and Ventilation

For various reasons, you may wish to encapsulate the sensor, either wholly or partially. The working field of view, if

covered with transparent material, should be highly transmissive of near-IR light at and near the 903 nm wavelength. Any

moisture that enters should have a way to drain passively.

The VLP-16 generates a moderate amount of heat during normal operation. Strategies for managing heat in hot weather

include employing a "thermal hat," exposing the sensor to moving air, and drawing heat from the sensor with a heat sink

(e.g. aluminum plate(s)).

The sensor reports internal temperatures passively on its web interface. The same readings may be obtained pro-

grammatically via curl commands (i.e. http GET requests). See

Sensor Communication on page 68

sensor's operating temperature range can be found on its data sheet.

Do not operate the sensor without sufficient ambient air flow or cooling.

5.4 Connections

This section covers the sensor’s physical connections.

Network Considerations on page 135

before connecting one or more Velodyne LiDAR sensors physically to your net-

Ethernet and Network Setup on page 134

for instructions on how to configure the sensor's Ethernet con-

nection.

30

VLP-16 User Manual