11

Replace the PTFE gasket if the following conditions occur:

•

Visible wear of the component (e.g. deformations, thinning),

•

Unusual noise and vibration during the operation of the dispersing instrument,

•

When the space between the gasket and the internal and external metal parts is excessive.

To disassemble the dispersing tool, use the appropriate tool disassembly kit supplied with the drive unit and read the

instruction manual supplied with each tool.

6. Error and warning messages

When the display shows an error message, the motor stops automatically. To restore the functionality of the instrument,

proceed as follows:

•

Turn the unit off using the main switch

•

Use

the suggestions described in the column “Solution”

•

Turn the unit on

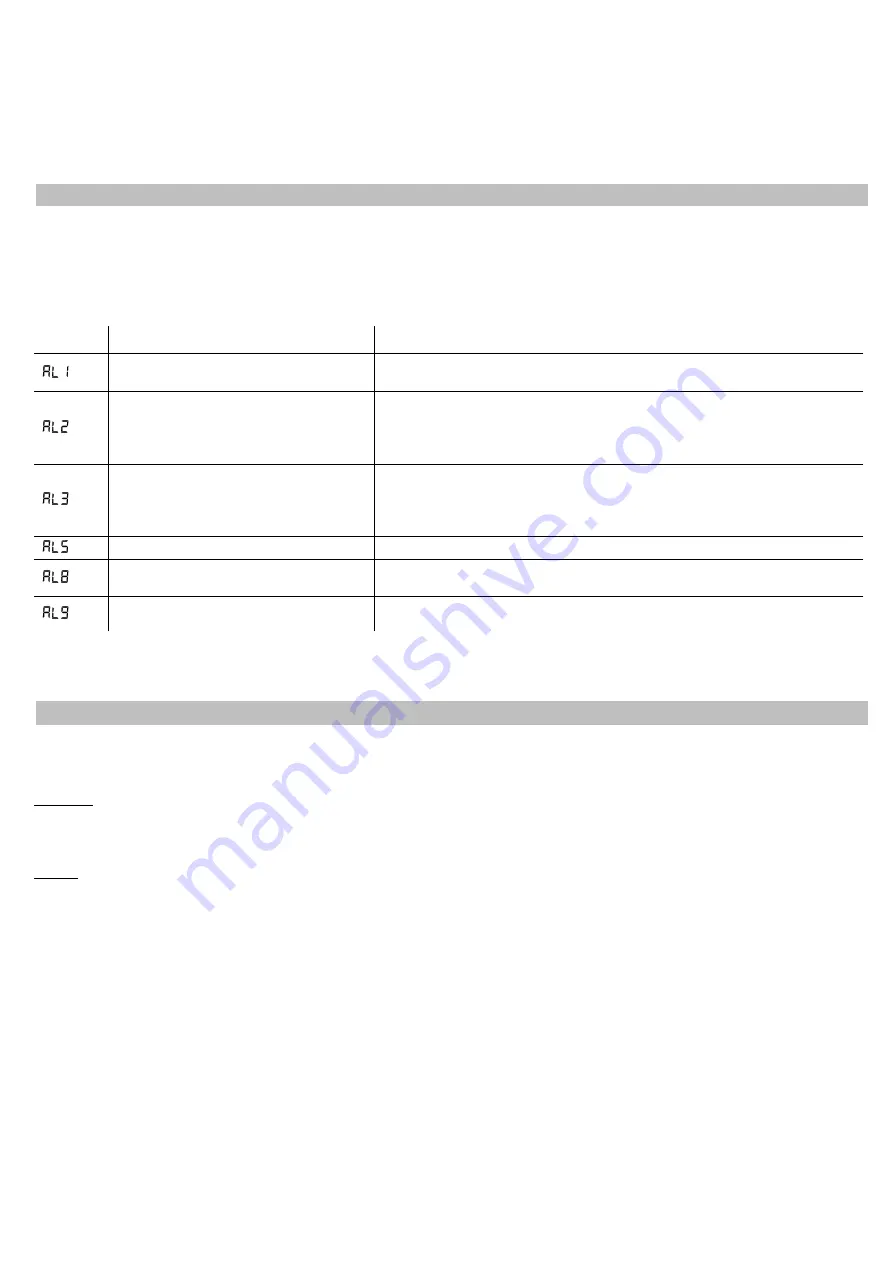

Code

Cause

Solution

The motor

doesn’t start or doesn’t

reach the set speed

•

Check that there

aren’t locks in the dispersing tool or structure

•

Check the operating time of the motor and brushes (chapter 0)

High internal motor temperature

•

Check that there

aren’t obstructions on the air vents for internal

ventilation

•

Check that there

aren’t locks in the dispersing tool or structure

•

Reduce speed or load

Motor overload

•

Check that there

aren’t obstructions on the air vents for internal

ventilation.

•

Check that there

aren’t locks in the dispersing tool or structure

•

Reduce speed or load

Problem on the main board

•

Contact

VELP Scientifica’s technical service department

Speed variation too high

•

Check that there are no locks in the dispersing tool or structure

•

Check the operating time of the motor and brushes (chapter 0)

Blackout or plug inserted with the

main switch in position I

•

Enter the plug when the main switch is in position 0

If an

error persists on the display, please contact VELP Scientifica’s technical service department.

7. Maintenance and cleaning

No routine or extraordinary maintenance is necessary for the unit. The maintenance is foreseen only on the dispersing tools

as described in Chapter 5.

Cleaning

Disconnect the unit from the power supply and use a cloth dampened with a non-flammable non-aggressive detergent.

During cleaning operations, prevent water and humidity residues from entering the unit.

Repair

Repairs must be carried out by authorized Velp personnel only.

The transport of the instrument by freight forwarders, couriers or others must be carried out using the original shockproof

packaging. Follow any instructions on the original packaging (e.g., palletizing).

It is the responsibility of the user to properly decontaminate the unit in case of hazardous substances remaining on the

surface or interior of the device. If in doubt about the compatibility of a cleaning or decontamination product, contact the

manufacturer or distributor.

Summary of Contents for OV 625

Page 37: ...37 1 OV 625 A OV 625 D20 B C H D E F G 3 LED 1000 rpm B C B D A G E F...

Page 38: ...38 2 OV625 A Mini H C Mini H C Mini H D B 5 3 E G 0 F SpeedServo 0 F...

Page 39: ...39 4 E F 2 5 LED 4 LED 2 5 B B D D20 20mm Aisi 316L D20 20mm...

Page 41: ...41 30 60 PTFE PTFE PTFE PTFE 6 4 4 I 0 VELP...

Page 47: ......