VEMCO – ASCENT–AR / AR2 Manual

28 July

2018

45

Click

Yes

. The reset dialog box disappears, and the release and VUE software are now synchronized

with a new date for battery replacement.

If you did NOT replace the battery

: If you had not connected to VUE after having a “Power OFF”

and “Power ON” event, and your current battery is still good, click

No

. The reset dialog box

disappears, and the release and VUE software are now synchronized with a new date for battery

replacement.

Your release is now ready for use.

8.2

ASCENT-AR case related troubleshooting

8.2.1

The threads have been damaged

It’s very important that the threads on the end-cap are not dented or the outer cylinder will not thread onto the

end-cap properly. If the threads on the end-cap are slightly dented, use a sharp knife, such as an X-Acto

knife, to remove the deformed plastic until the sides of the thread are smooth and below the normal line of the

thread. It is important that there is nothing sticking out of the thread to damage the thread on the outer

cylinder or prevent the case from closing.

8.2.2

I think the case might be pressurized

When handled correctly, the ASCENT-AR pressure case and seal have a static depth rating of 500 meters

(730 psi). If the release experiences a pressure greater than this, then water may enter the case. NOTE:

Physical shocks to the release, such as bumping into a solid object, when it is at any depth can result in a

considerably higher pressure on the casing than just the depth pressure. Also, if the O-rings or their mating

surfaces are dirty or damaged, then water may enter the release case.

If water enters the release case under high pressure and the Release Valve was unable to open and equalize

the pressures, then some water and compressed air may still be in the case when it is returned to the surface.

This can be identified by its increased weight and a sloshing sound when the case is moved. The ASCENT-

AR case will also be very difficult to open, if at all possible. If you are suspicious there is compressed air in

the release case, then check for air or water leaking from seam in the case where the end-cap and outer

cylinder meet.

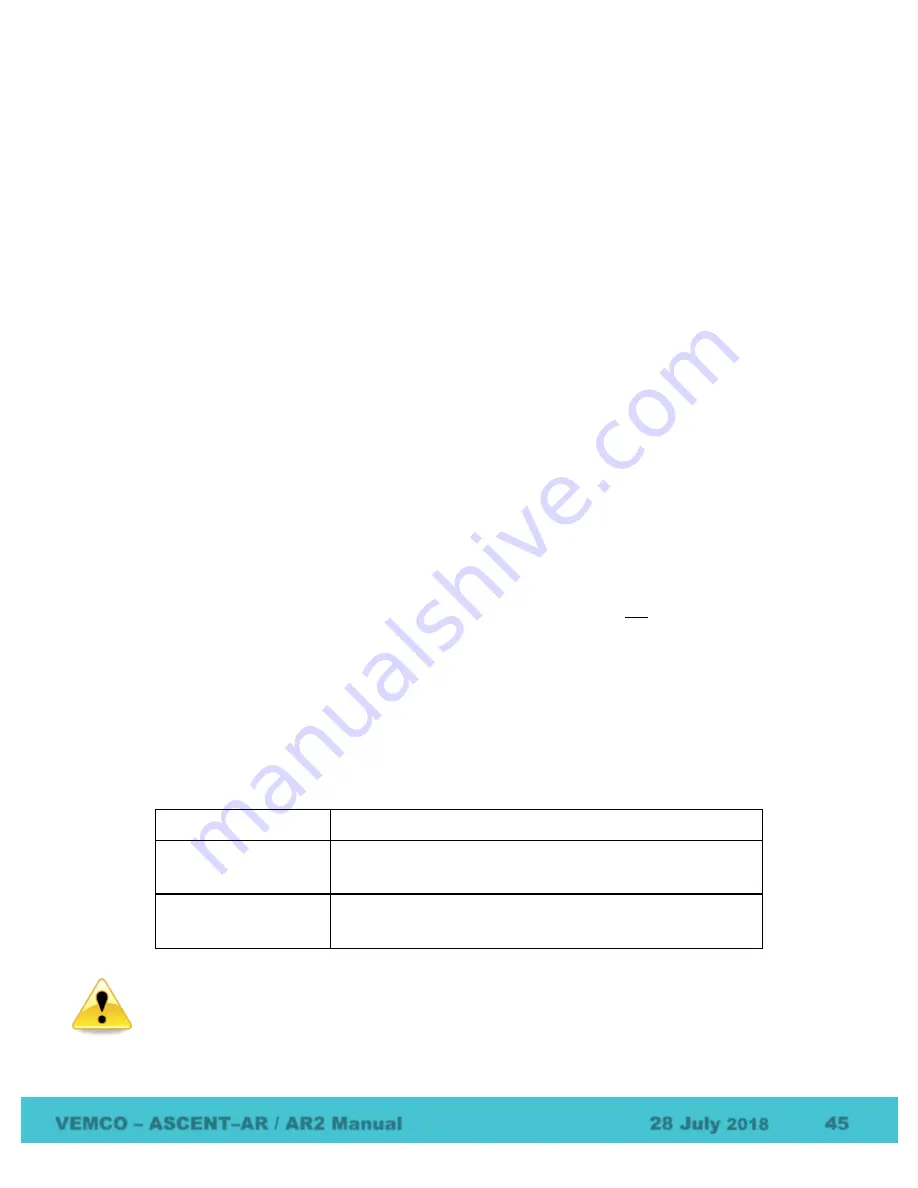

To check for...

Do this

water

leakage

dry the seam completely and watch for drops of water around

the seam

air

leakage

spread soapy water around the seam and watch for bubbles

indicating air escaping

If air and/or water are found leaking from the release case, do not attempt to remove the end-cap.

Instead, place the release in a safe place and cover it with a protective layer of towels, tarpaulins, etc.

until the leaking stops. If water is still in the case after the air and/or water have finished leaking

from the case, then attempt to open the case with the steel rod kit. If it will open, do so very slowly to