483515 • DFDR FDR FSDR, Rev. 3, January 2022

Copyright 2022 © Venco Products

8

As a result of our commitment to continuous improvement, Venco reserves the right to change specifications

without notice.

Our Commitment

Phone: 1.833.881.0565 • Fax: 715.355.2399 • E-mail: info@vencoproducts.com • Website: www.vencoproducts.com

Damper Maintenance

Dampers do not typically require maintenance as long as they are kept dry and clean. If cleaning is necessary, use

mild detergents or solvents. If lubrication is desired for components such as axle bearings, jackshaft bearings and

jamb seals, do not use oil-based lubricants or any other lubricants that attract contaminants such as dust.

Dampers and their actuator(s) must be maintained, cycled, and tested a minimum in accordance with:

• The latest editions of NFPA 80, 90A, 92, 101, 105, UL864, AMCA 503-03 and local codes.

• Actuator manufacturer recommendations.

Damper Troubleshooting

The following is a possible cause and correction list for common concerns with dampers.

Symptom

Possible Cause

Corrective Action

Damper does not

fully open and/or

close

Frame is 'racked' causing blades to

bind on jamb seals

Adjust frame such that it is square and plumb

Actuator linkage loose

Close damper, disconnect power, adjust and

tighten linkage

Defective motor

Replace

Screws in damper linkage

Damper installed too far into wall. Move out to

line as designated on damper label

Contaminants on damper

Clean with a non-oil based solvent (see Damper

Maintenance)

RRL or TOR sensor

tripped

Heat

Push reset button located on backside of RRL or

TOR

Damper does not

operate

No power supplied to the actuator

Add power supply

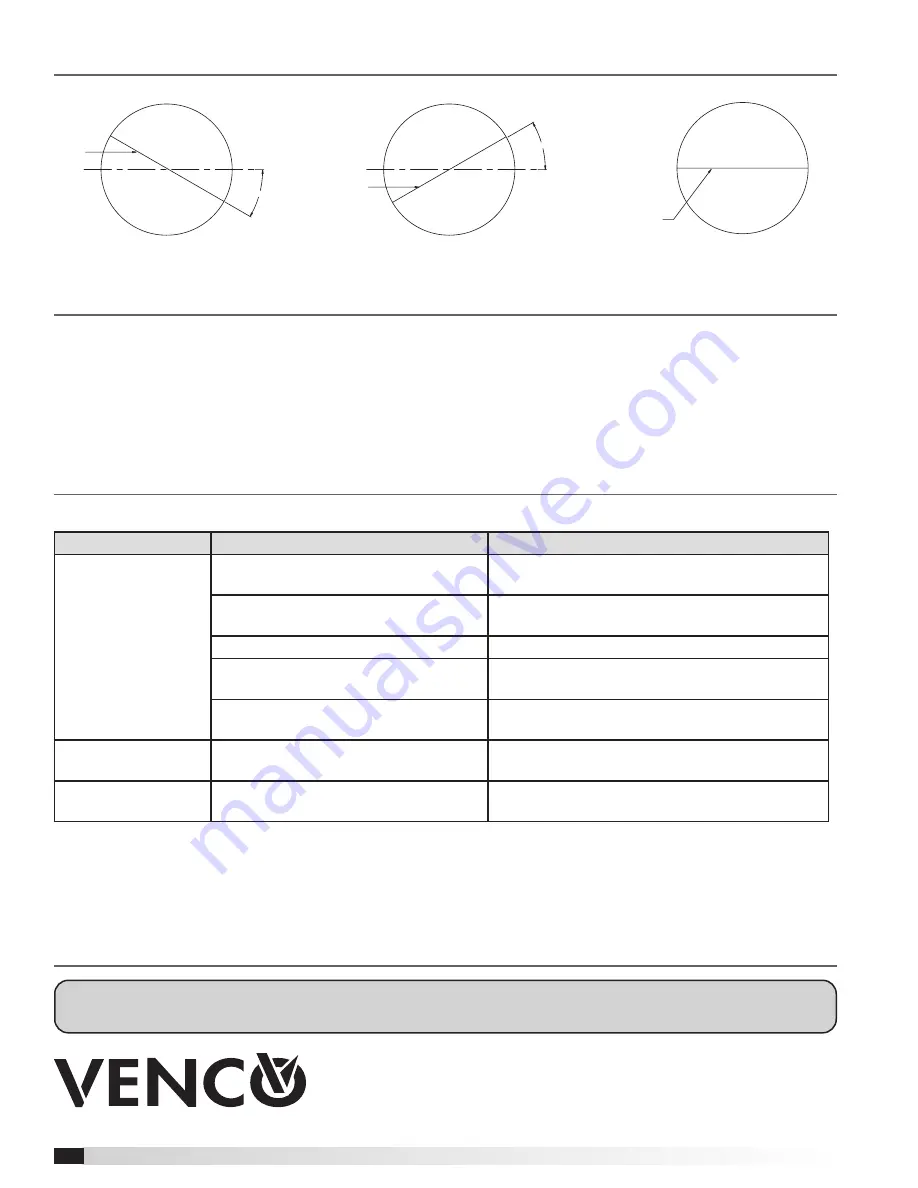

Blade Orientation

Axle

30°

30° Off Horizontal (Maximum)

Axle

30°

30° Off Horizontal (Maximum)

Axle

Normal