2.0 Site Requirement

2.1

Information

1. The unit must be sited and connected by a

suitably competent person and be in accordance

with current UK Building Regulations and I.E.E.

Wiring Regulations (BS 7671).

2. The unit is intended for permanent connection

to the mains electrical supply.

3. Wiring to the unit in the UK must be via a

switched fused spur. The switched fused spur

must have a 3mm minimum contact gap in all

poles.

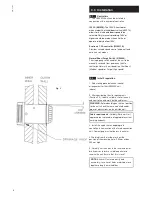

Fig. 2

4. Ensure that the mains electrical supply is

compatible with the rating label attached to the

product. Warning: this appliance is class 1 and

it must therefore be earthed.

5. The unit must be sited such that the ambient

temperature will not exceed 40° C.

6. Do not site the appliance in the vicinity of

excessive levels of airborne oil or grease.

7. If the unit is installed in a room containing a

fuel burning appliance, the installer must ensure

that air replacement is adequate for both

appliances.

8. The unit must not be installed at a level below

500mm from the floor.

9. The internal grille surround must be sited at

least 125mm away from any wall or projecting

surface.

10. The external grille of the unit must be sited at

least 600mm away from any flue of gas or solid

fuel appliances. This is to avoid back flow of

gases entering the room.

11. All safety regulations and requirements must

be strictly followed to prevent hazards to life and

property both during and after installation and

during subsequent maintenance or servicing.

12. Ensure the mains electrical supply is switched

off before commencing installation or

maintenance.

5