7

HUMIDITY SET-POINT ADJUSTMENT (HT/HTP MODELS) (FIG. 8)

BEFORE ADJUSTING THE CONTROLLER, SWITCH OFF THE MAINS SUPPLY.

HUMIDISTAT SHOULD ONLY BE ADJUSTED BEFORE OR DURING INSTALLATION.

1.

Remove the fan grille. The controller is factory set to switch on at about 70% RH.

The humidity set point can be adjusted from 65-95%RH by altering the adjuster on

the control PCB.

2.

To LOWER the set-point use a small screwdriver to turn the adjuster Fig.8. ANTI-

CLOCKWISE. This makes the controller MORE sensitive.

3.

To RAISE the set-point use a small screwdriver to turn the adjuster Fig.8.

CLOCKWISE. This makes the controller LESS sensitive.

4.

Replace the fan grille.

PULLCORD (TP & HTP MODELS ONLY)

– The pullcord activates the inbuilt timer overrun

(adjustment settings above). Once activated, the fan will remain on boost for the preset overrun

time. If the pullcord is pulled again during the overrun time period, the timer will reset the

countdown timer back to the preset value. There is no way of switching the fan back to trickle

manually.

D. SERVICING AND MAINTENANCE.

WARNING: THE FAN AND ANCILLARY CONTROL EQUIPMENT MUST BE

ISOLATED FROM THE POWER SUPPLY DURING MAINTENANCE.

1. At intervals appropriate to the installation, the fan should be inspected and cleaned to

ensure there is no build up of dirt or other deposits.

Ensure that the fan is switched off from the supply mains before removing the grille.

2. Carefully push the front panel of the grille upwards away from the base part of the grille

(fig. 7).

3. Wipe the inlets and front face with a damp cloth until clean.

The fan has sealed for life bearings, which do not require lubrication.

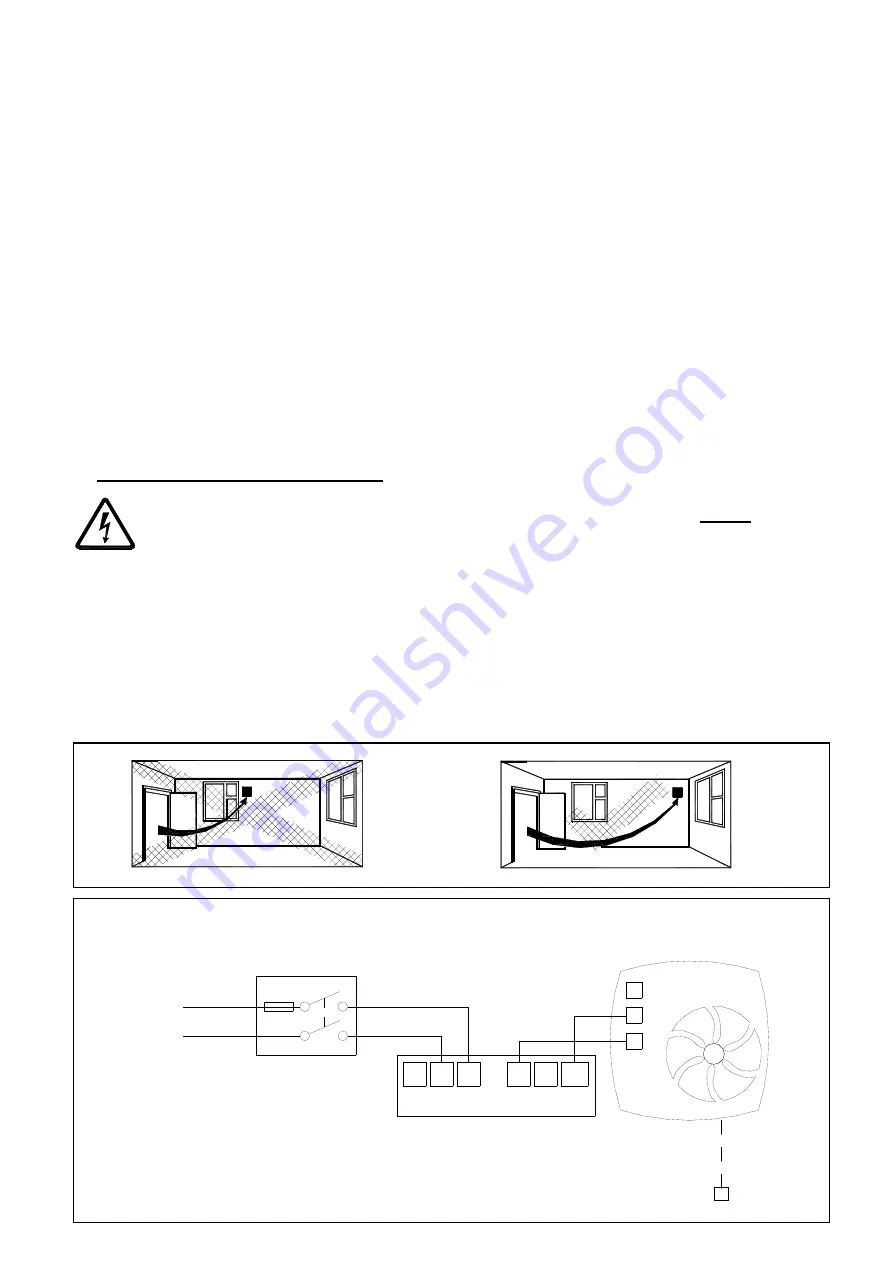

~

N

L

1 Phase Supply

(220-240V 50Hz).

FUSE

Switched

Fused Spur

(3A)

LS

12V

0V

Controller

Fan

12V D.C

SELV Supply

N

L

LS

LS

N

L

2

1

3

Fig.2 Continuous trickle (6l/s or 9l/s)

with no remote boost facility

Note:-

(T, TP, HT & HTP – But TP & HTP can be boosted via pullcord)

Fig. 1

Siting

the

fan.

PULLCORD

TP & HTP ONLY

Summary of Contents for Centra Lo-Carbon SELV HT

Page 2: ...2...

Page 10: ...Notes...