Page 10

Specifications are subject to change without notice.

Installation Instructions

Distributed by Simx Limited

enquiry@manrose.co.nz | www.manrose.co.nz

Installation Instructions

Specifications are subject to change without notice.

Page 11

enquiry@manrose.co.nz | www.manrose.co.nz

Distributed by Simx Limited

MultiVent Continuous Extract Ventilation

MultiVent Continuous Extract Ventilation

Using instructions from the section “UNIT ADJUSTMENT” make the following changes:

LS1 change from Low to BOOST

D2 change from Purge to BOOST

With this completed the MultiVent once switched ON will operate in NORMAL speed (35%) when the bathroom FAN switch is turned on the

MultiVent will operate at BOOST (70%) speed clearing away steam and humidity if the kitchen FAN switch is turned on the MultiVent will operate

at BOOST (70%) if both bathroom and kitchen FAN switches are turned on together the MultiVent will operate at PURGE (100%) speed helping

to clear away steam and cooking odours. The toilet FAN switch will also turn the MultiVent on to BOOST (70%). Please note that only having the

2 larger rooms (bathroom and kitchen) switched on will activate PURGE (100%) speed.

FAULT CODES

If the MultiVent unit detects a fault it will display an error message on the HMI display.

Fault Code

Description

F01

Control fault – Unit failed startup check

F02

Motor Fault – No RPM

F03

Humidity/Temp sensor Fault – No value

F04

Temp or Humidity sensor connected via RF/RS485 is offline/Lost

COMMISSIONING – TYPICAL 3 ROOM SYSTEM

In the following step we will provide an example of how to wire and control an MultiVent system hardwired to a Bathroom, Kitchen and Toilet.

The MultiVent will utilize Humidity – Rapid Rise in its response and the 2 larger rooms (Bathroom and Kitchen) will also provide a PURGE speed

function if these 2 rooms are switched on together.

Before commencing please ensure that all power is OFF and ensure that it is electrically safe before starting.

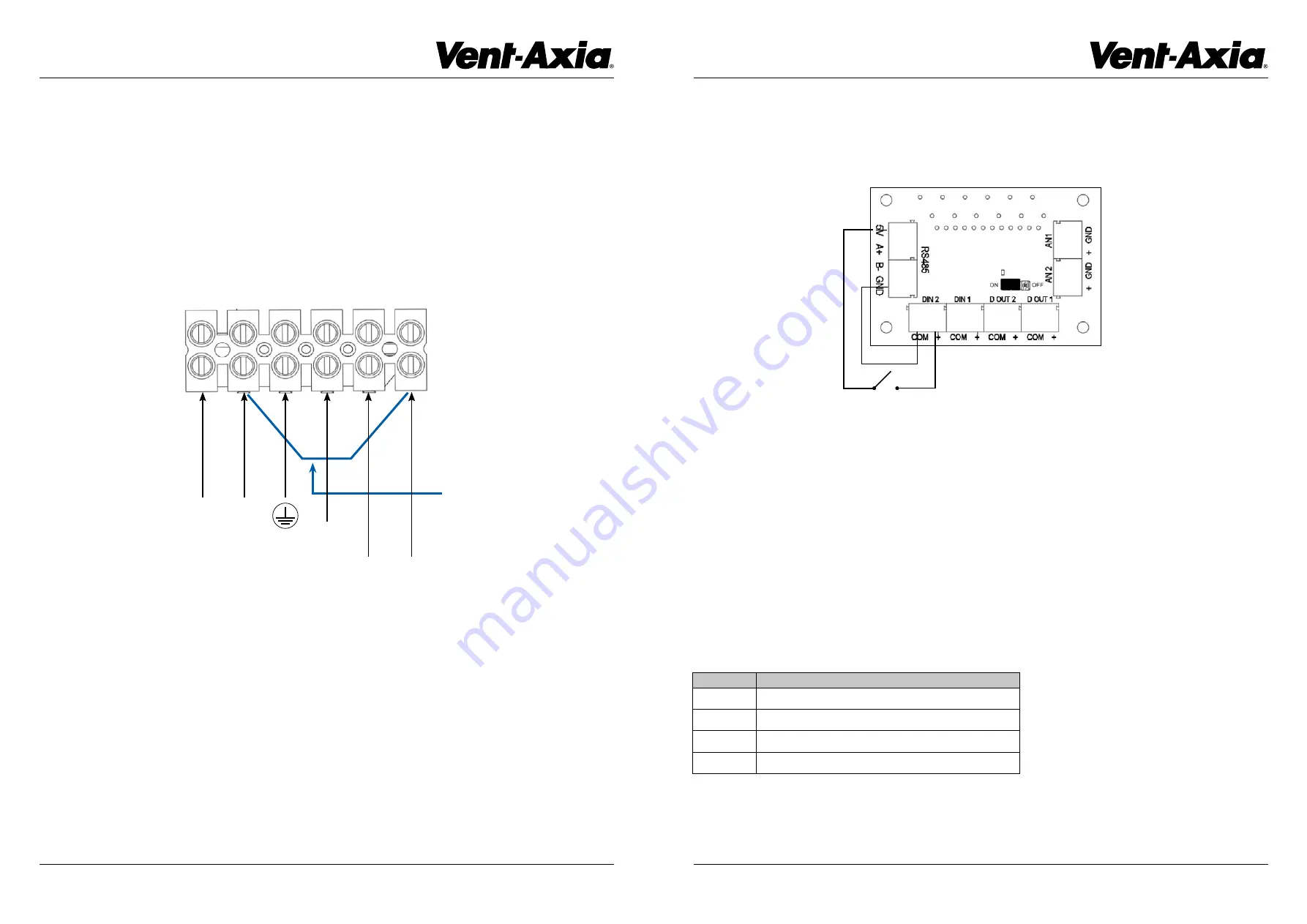

Wire the 230VAC connections as per the diagram below. Wire mains connections from a suitable source (lighting circuit) or add a new dedicated

circuit from an RCD protected 10A MCB with the cable to L (live - BROWN), N (neutral - BLUE) and E (protective earth – GREEN/YELLOW).

Wire a 230V connection from a switch located in the Bathroom that could be either a dedicated FAN switch (or a connection from a LIGHT switch)

and connect the L (BROWN) wire back to LS1. Do the same from a switch located in the Kitchen and connect the L (BROWN) wire back to LS2.

Hardwire a NEUTRAL LINK (BLUE or BLACK) from the N (neutral - BLUE) mains connection to the connection labelled NS (neutral switched).

L

N

E

LS1

LS2

NS

L

N

From

Bathroom

From

Kitchen

NS

NEUTRAL LINK

For the toilet the MultiVent will use its Extra Low Voltage connections for control. Using a short piece of wire connect a 0.5mm (or similar sized wire)

from the GND terminal at the RS485 connection to the COM terminal adjacent to DIN 2 (digital input 2) + connector. Using a twin red TPS cable

connect one RED core to the + connector at DIN 2 and connect the other RED core to the 5V terminal at the RS485 connection. Run the other end

of the cable to the toilet FAN switch and connect the 2 red cores to the C (common) and the normally open (usually labelled 1) connections at this

switch. See diagram below.

C

TOILET

1

RED

RED