6. Withdraw the heat exchanger from the housing by grasping and gently but firmly pulling on its

central vertical member.

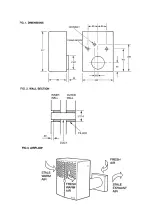

7. Offer the housing to the inner mounting surface and, with the duct spigot located over the duct,

mark the two fixing hole positions on the mounting surface.

8. Prise the grille out of the grille assembly and remove the insect screen.

9. Offer the grille base to the external mounting surface and,with the duct spigot located inside the

duct, mark two of the four fixing hole positions on the mounting surface.

10.Suitably drill and plug the fixing holes in both mounting surfaces.

11.Pass the supply cable through the grommet in the rear face or top face of the housing and fix the

housing to the inner mounting surface using suitable round head woodscrews.

12.Fix the grille base to the external wall surface also using suitable round head woodscrews.

13.Replace the insect screen and grille in the grille base. The grille blades must slope downwards

away from the external mounting surface to shed rainwater.

WIRING INSTRUCTIONS (SEE FIG.5)

1. Ensure the mains electrical supply is switched off.

2. Remove the terminal block cover after unscrewing the retaining screw.

3. Remove the minimum amount of sheath and insulation from the supply cable and leads.

Slacken the cable clamps and feed the cable through the clamps. Connect the conductors,coloured

red-live(L),black-neutral(N) and green/yellow-earth(E/ ), to the appropriate terminals, marked L1,

L2, N and E/ of the terminal block in accordance with the wiring arrangements shown in Fig. 5.

4. Position the cable in the cable clamps such that the cable sheath will be clamped and tighten the

cable clamp nuts to secure the cable in position.

5. Replace the terminal block cover and tighten the retaining screw.

6. Replace the heat exchanger.

7. For top cable entry make a cutout in the top of the cover to clear the cable.

8. Refit the cover and tighten the four retaining screws.

9. Switch on the mains electrical supply and check the fan operation.

CLEANING

Apart from removing odours, providing fresh air and recovering heat this appliance extracts airborne

impurities such as dust, dirt and grease. These gradually bulid up and detract from the efficiency

and appearance of the appliance. Therefore, to ensure peak performance, the appliance should

be cleaned regularly at periods determined by the level of contamination experienced and according

to the following procedure: