4.0 Electrical

8

4.1

Electrical Connections

230V 50Hz 12W (normal) 31W (boost)

1. The

HR

100

W

is supplied with an in-built two

speed motor fitted.

2. Wiring must be via a 3A fused switched spur

with a 3mm contact separation in each pole.

The wiring should be suitably (Basec or Har)

approved cable of appropriate current carrying

capacity.

3. Ensure that the mains power supply is

isolated prior to installation.

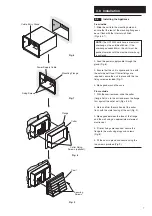

4. Remove the terminal block cover (Fig. 10)

and connect incoming wires to the appropriate

terminals, see relevant wiring diagram

(for

HR

100

WH

see page 11).

5. Replace th

e terminal block cover and

tighten

the cable gland (Fig. 10).

6. Slide the heat exchanger into the unit,

ensuring the ‘Top’ label is facing the front and

pointing upwards (Fig. 11).

7. Locate the grille on to the front of the unit

and secure with the two screws provided

(Fig. 11).

8. Switch on the mains electrical supply and

check the operation of the unit.

Fig. 10

T

O

P

Fig. 11

Terminal Block

Cover

Heat Exchanger

Securing Screws

Grille

HR

100

W

Terminals

3 amp fused supply

L

L

N

Neutral

Live

Earth

1

2

HR

100

W

Terminals

3 amp fused supply

NBSW/PCSW

L

L

N

Neutral

Live

Earth

1

2

HR

100

W

/

HR

100

W

H

Terminals

3 amp fused

supply

L

L

N

Neutral

Live

Switched Live

Light

Earth

1

2

1

2

3

L

N

HR

100

W

Terminals

VCON100 Terminals

3 amp fused supply

L

L

N

Neutral

Live

Earth

1

2

HR

100

W

Terminals

3 amp fused supply

L

L

N

Neutral

Live

Earth

1

2

HR

100

W

,

HR

30

W

and

HR

100

W

H units must not be wired in

conjunction with a light switch, units will fail.

HR

100

W

continuous normal speed.

HR

100

W

wiring to NBSW/PCSW switches for

manual, normal and boost switching.

HR

100

W

wiring to VCON100 controller for manual,

on/off, normal and boost switching.

HR

100

W

continuous boost speed.

Cable Entry Gland

Summary of Contents for HR100W

Page 14: ...NOTES 13...

Page 15: ...NOTES 14...