The unit is supplied with four, 6-month Timestrip indicators. A Timestrip is a single use self-adhesive label that once

activated will turn red over 6 months. It should be used to keep track of when the filter and cell need cleaning/replacement.

Using the self-adhesive backing the strip can stuck near the units controls, or in a easily visible place.

A normal cleaning schedule for a unit would be as follows:

After installation

Activate the 1st Timestrip

After 6 months

Clean cell, clean filter, activate 2nd Timestrip

After 12 months

Clean cell, clean filter, activate 3rd Timestrip

After 18 months

Clean cell, clean filter, activate 4th Timestrip

After 24 months

Clean cell,

replace filters

, the new filters will be supplied with 4 additional Timestrip indicators

Note: The above is the minimum requirement; more frequent cleaning intervals may be needed depending on the

environment the unit is installed in.

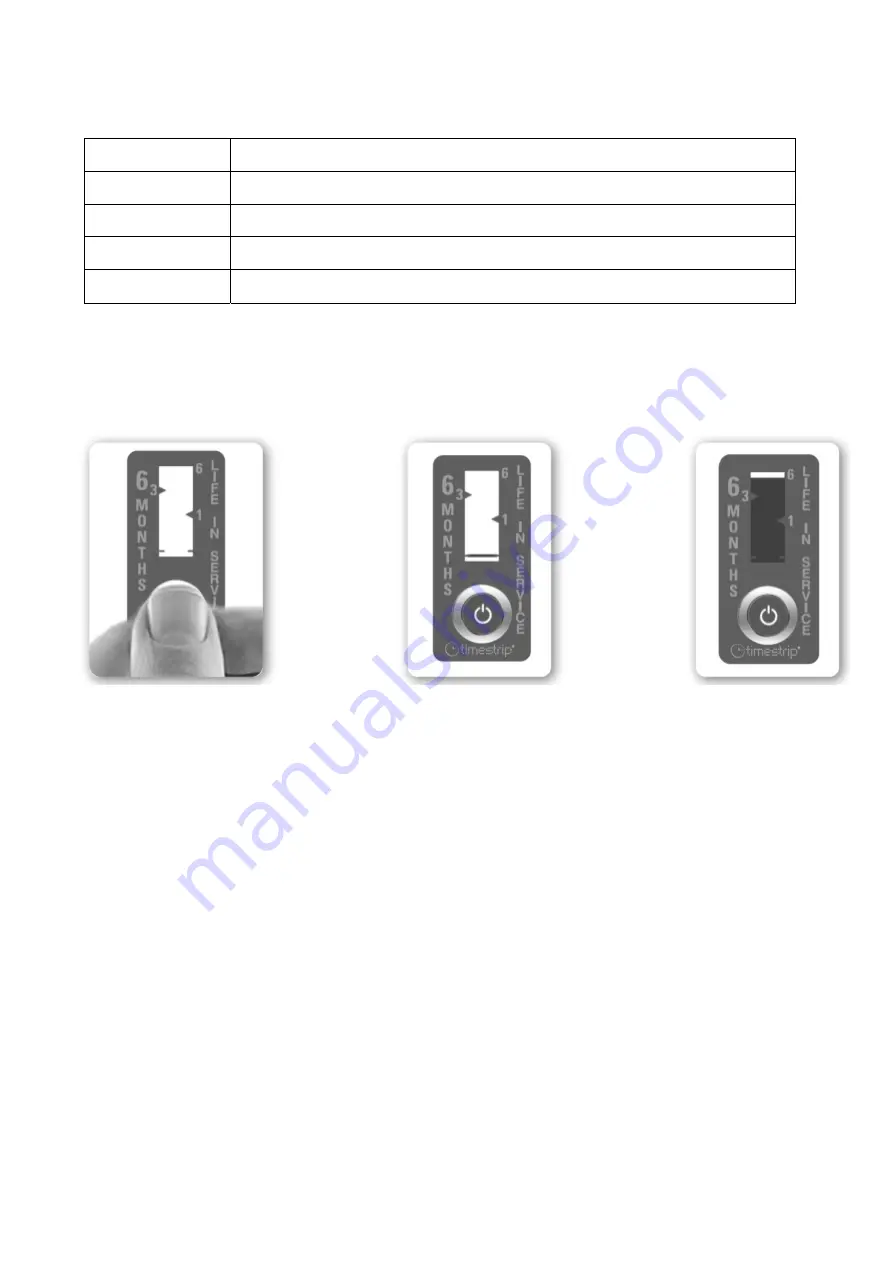

Activating the Timestrip.

1. Activation: Fully squeeze the activation button between thumb and finger. A red line will appear within 1-2 minutes to

show that the Timestrip has been activated.

2. Peel off the backing liner and stick the Timestrip to the Unit or near the controls of the unit. The location should make it

obvious to the person responsible for maintenance that the unit needs attention.

3. Once activated, the red dye will indicate elapsed time by moving through the white window and past each time marker.

The progress of the red dye is irreversible and each Timestrip can only be used once.