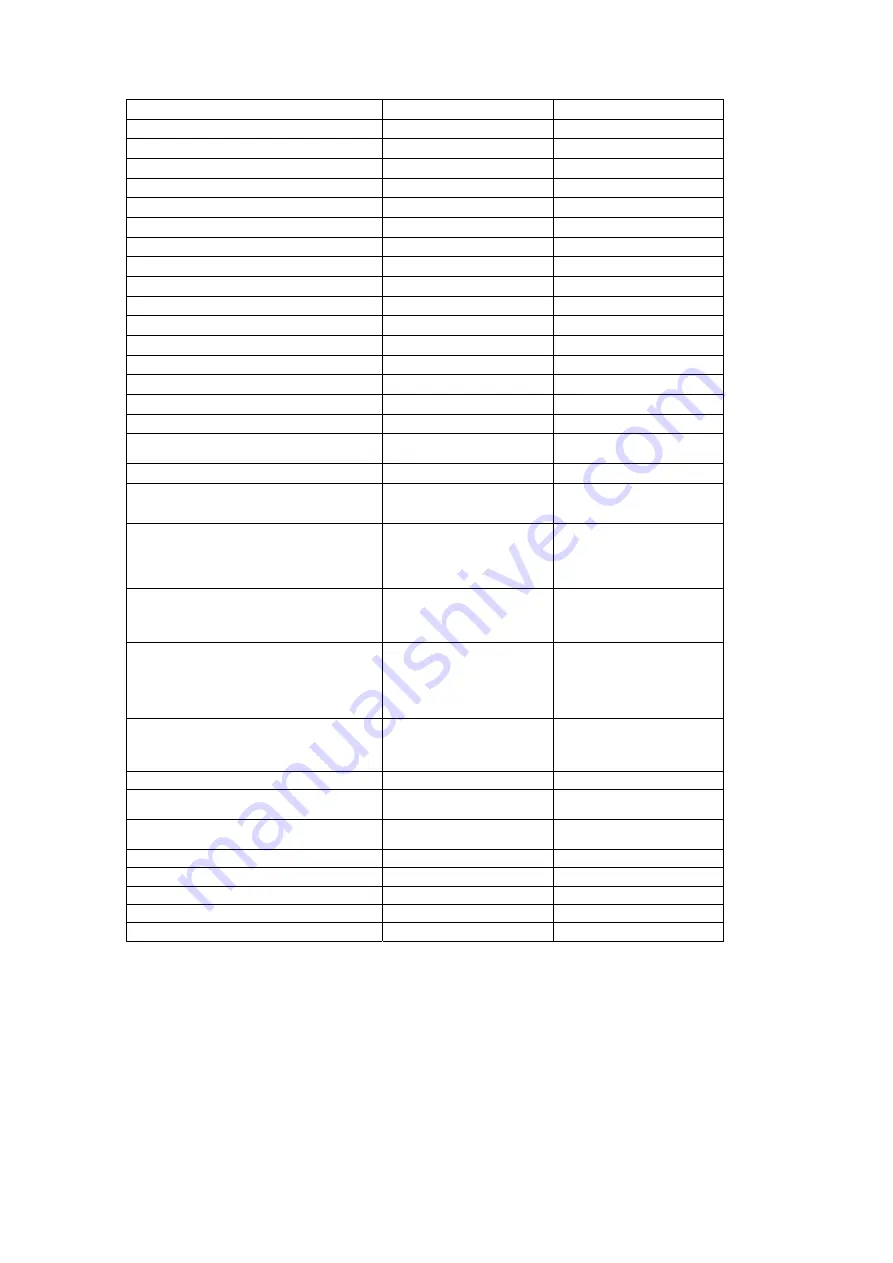

PRODUCT

FICHE

For

Residential

Ventilation

Units

(Complying

Commission

Delegated

Regulation

(EU

No

1254/2014)

Name:

Vent

‐

Axia

Vent

‐

Axia

Model

ID

(Stock

Ref.)

:

HR300

–

370394

CDC

HR300

–

370394

LDC

SEC

Class

B

A

SEC

Value

('Average')

‐

33.67

‐

38.24

SEC

Value

('Warm')

‐

12.17

‐

15.59

SEC

Value

('Cold')

‐

71.99

‐

78.57

Label

Required?

(Yes/No=Out

of

scope)

Yes

Yes

Declared

as:

RVU

or

NRVU/UVU

or

BVU

RVU/BVU

RVU/BVU

Speed

Drive

Variable

Speed

Variable

Speed

Type

HRS

(Recuperative,

Regenerative,

None)

Recuperative

Recuperative

Thermal

Eff:

[

(%),

NA(if

none)]

70.00

70.00

Max.

Flow

Rate

(m3/h)

298.80

298.80

Max.

Power

Input

(W):

(@Max.Flow

Rate)

108.00

108.00

LWA:

Sound

Power

Level

(dB)

57.52

57.52

Ref.

Flow

Rate

(m3/s)

0.06

0.06

Ref.

Pressure

Diff.

(Pa)

75.00

75.00

SPI

[W/(m3/h)]

0.24

0.24

Control

Factor

&

Control

Typology:

(CTRL/

Typology)

Control

Factor;

CTRL

0.85

0.65

Control

Typology

Central

Demand

Control

Local

Demand

Control

Declared:

‐

Max

Internal

&

External

Leakage

Rates(%)

for

BVUs

or

carry

over

(for

regenerative

heat

exchangers

only),

‐

&Ext.

Leakage

Rates

(%)

for

Ducted

UVUs;

<5%

Internal,

<5%

External

<5%

Internal,

<5%

External

Mixing

Rate

of

Non

‐

Ducted

BVUs

not

intended

to

be

equipped

with

one

duct

connection

on

either

supply

or

extract

air

side;

TBC

TBC

Position

and

description

of

visual

filter

warning

for

RVUs

intended

for

use

with

filters,

including

text

pointing

out

the

importance

of

regular

filter

changes

for

performance

and

energy

efficiency

of

the

unit

N/A

N/A

For

UVUs

(Instructions

Install

Regulated

Supply/Extract

Grilles

Façade)

N/A

N/A

Internet

Address

(for

Disassembly

Instructions)

www.vent

‐

axia.com

www.vent

‐

axia.com

Sensitivity

p.

Var20/

‐

20

Pa:

(for

Non

‐

Ducted

VUs)

TBC

TBC

Air

Tightness

‐

ID/OD

‐

(m3/h)

(for

Non

‐

Ducted

VUs)

TBC

TBC

Annual

Electricity

Consumption:

AEC

(kWh/a)

2.83

1.84

Annual

Heating

Saved:

AHS

(kWh/a)

AHS:

Average

42.17

42.17

AHS:

Warm

19.07

19.07

AHS:

Cold

82.50

82.50