3.0 Installation

CG

-1

-1

/0

1

3.1

Controllers

1. The HR300 unit can be installed in conjunction

with a number of controllers.

VCON6(370356):

The VCON6 controller can be

used to provide Off/Low/Normal/Boost/Sensor

control. (The HS6 humidistat or TIM2 over-run

timer can be used in conjunction with the VCON6

controller to provide automatic control.

150VA (

563538):

The 150VA transformer,

when used with a trickle/boost switch (455213),

allows for a trickle and boost speed to be

selected. Only terminals providing 140V or

higher should be used as the unit will not

operate reliably bellow 140V.

Ecotronic 1.5A controller (W300310):

Provides variable speed control and on off and

auto (sensor) modes.

TIM2(370346):

The TIM2 is an overrun timer

which can also be used to control the HR200

unit via a remote sensor e.g. Humidity Sensor.

3.2

Initial Preparation

1. Select an approved electrical control

arrangement for the HR300 unit (above).

2. After considering the site requirements

(Section 2.0), select a suitable site for the unit

and controllers and work out the cable runs.

WARNING:

Before deciding on the final position

for the unit, check there are no buried cables,

pipes or obstructions on the outside wall.

Cable requirements:

Suitably (Basec or Har)

approved four core cable of appropriate current

carrying capacity.

3. Install the cable runs and appropriate

controllers in conjunction with a fused connection

unit. Contact gap must not be less than 3mm.

4. Working from the inside, mark out the

position of the mounting hole - 280mm wide x

380mm high (see Fixing Template).

5. Carefully cut the holes in the inner and outer

brick courses to form a suitable aperture to

receive the unit. Ensure that this is level.

NOTE:

Bricks will cut more easily and

accurately if a series of holes are drilled close

together along the marked lines.

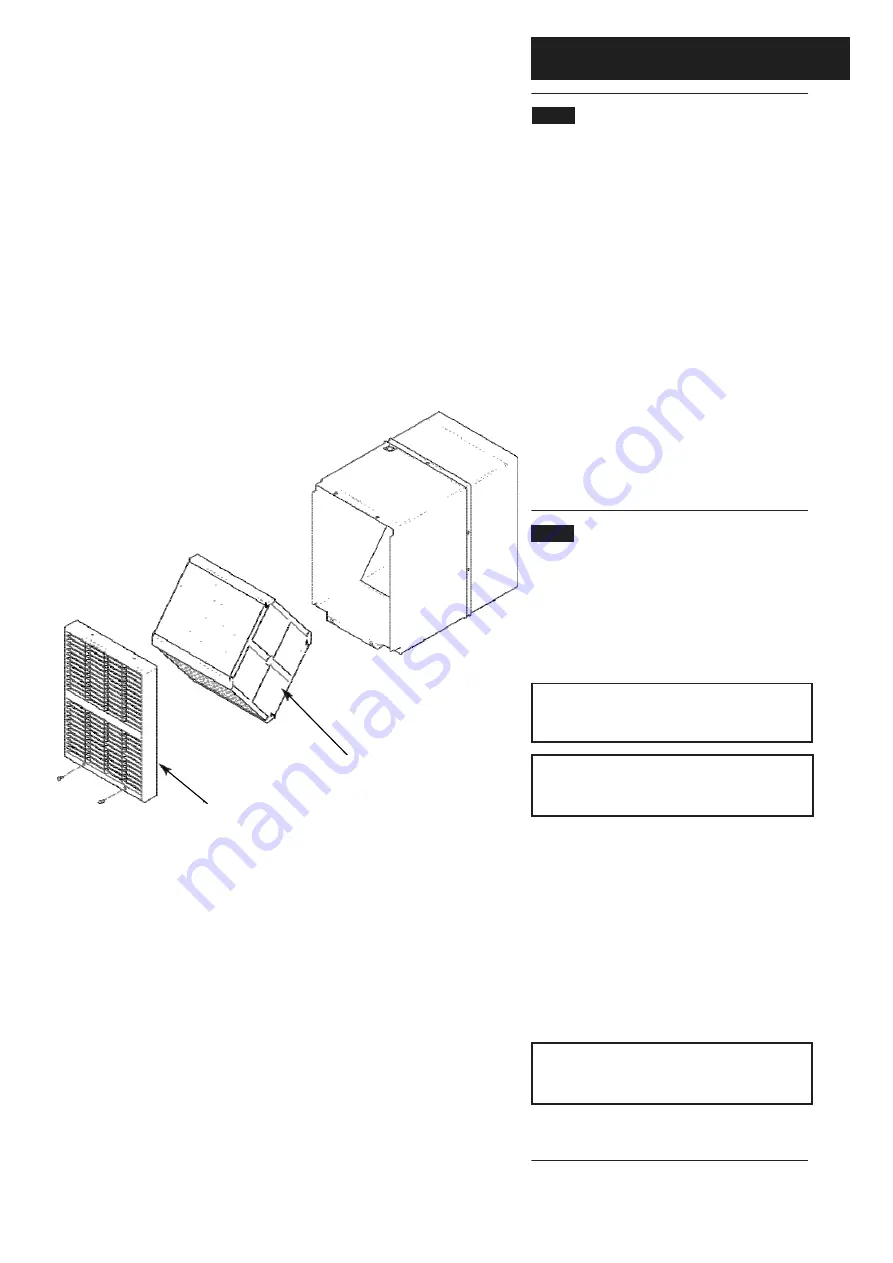

6. Remove the grille, heat exchanger, from the

unit (Fig. 3).

Heat Exchanger

Grille

Fig.3.