3.0 Installation

7

3.3

Installing the Appliance

From Inside

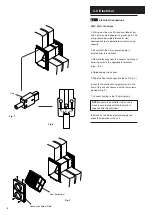

1. Slide the unit into the mounting hole and

ensure that the minimum overhang requirements

are achieved inside and out (Fig. 5).

2. The

HR

300RW6 requires an overhang internal

and external (Fig. 6):

Internal

50mm

External

55mm

3. Pierce the blind grommet on the left hand side

on the top of the unit and feed the supply cable

through the grommet (Fig. 5)

4. Ensure that the unit is square and true with the

outside wall face. If firmer fixings are required,

secure the unit in place with the two fixing screws

provided.

NOTE:

Ensure the fixings DO NOT inhibit

removal or replacement of the heat exchanger.

5. Make good around the case.

6. Fit the bezel on the inside to cover the making

good by pressing the bezel over the case (Fig. 7).

CAUTION:

Ensure the case does not distort

during fixing and making good.

From Outside

1. Slide the panel flange (flange first) on to the

unit and press the flange firm against the outer

wall (Fig. 7).

2. Secure the panel flange to the wall using the

fixing screws provided. If necessary the panel

flange can be secured to the case by self tapping

screw 25mm long maximum.

280mm

380mm

Fig. 5

50mm

55mm

Fig. 6

Blind Grommet

Fig. 7

Panel Flange

Bezel

Internal

External

3° Min

For Drainage