7

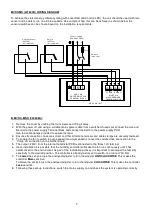

MVDC-MS (437634B) WIRING DIAGRAM

To achieve the stated energy efficiency rating with Local Demand Control (LDC), the unit should be used with two

sensor and be able to run on all three speeds. An example of how this can be achieved is shown below, the

sensors/switches can be chosen based on the installation requirements.

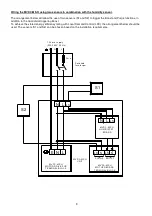

B. MVDC-MS H (443298A):

1. Remove the cover by undoing the four screws and lifting it away.

2. With the power off and using a suitable mains power cable from a switched, fused spur connect the Live and

Neutral to the power supply Terminal block and connect the Earth to the power supply PCB.

Use the cable clamps provided to secure the lead.

3. Ensure all connections have are correct and that all terminal screws and cable clamps are securely fastened.

4. To enable the fan to switch to purge speed (maximum speed) connect the switched live connection to the

‘Purge’ LS connection on the mother board.

5. The output (230V) from the internal humidistat PCB is connected to the ‘Boost’ LS terminal.

6. Upon installation it is possible that the humidity controller will make the fan run continuously until it has

acclimatised to the environment. As part of the installation process it is important to set/adjust the humidity

sensitivity to the desired position. The controller is already factory set to switch on at about 70% R.H.

7. To

Lower

the set-point use the enclosed adjuster to turn the adjuster

ANTICLOCKWISE

. This makes the

controller

More

sensitive.

To Raise the set-point use the enclosed adjuster to

turn the adjuster

CLOCKWISE

. This makes the controller

Less

sensitive.

8. Following these set-up instructions, switch the mains supply on and check the system is operating correctly.

Fuse

L

N

E

1 Phase supply

(220-240V 50 Hz)

Switched

fused spur

MVDC-MS

MOTOR DRIVE PCB

TERMINAL BLOCK

E N L

Switch

(455213)

(Not supplied)

LS N LS N

MVDC-MS

MOTHERBOARD

TERMINAL BLOCK

PURGE

BOOST

MVDC-MS UNIT

Humidity Sensor

(563550)

(Not supplied)

Summary of Contents for Lo-Carbon MULTIVENT MVDC-MS

Page 2: ...2...