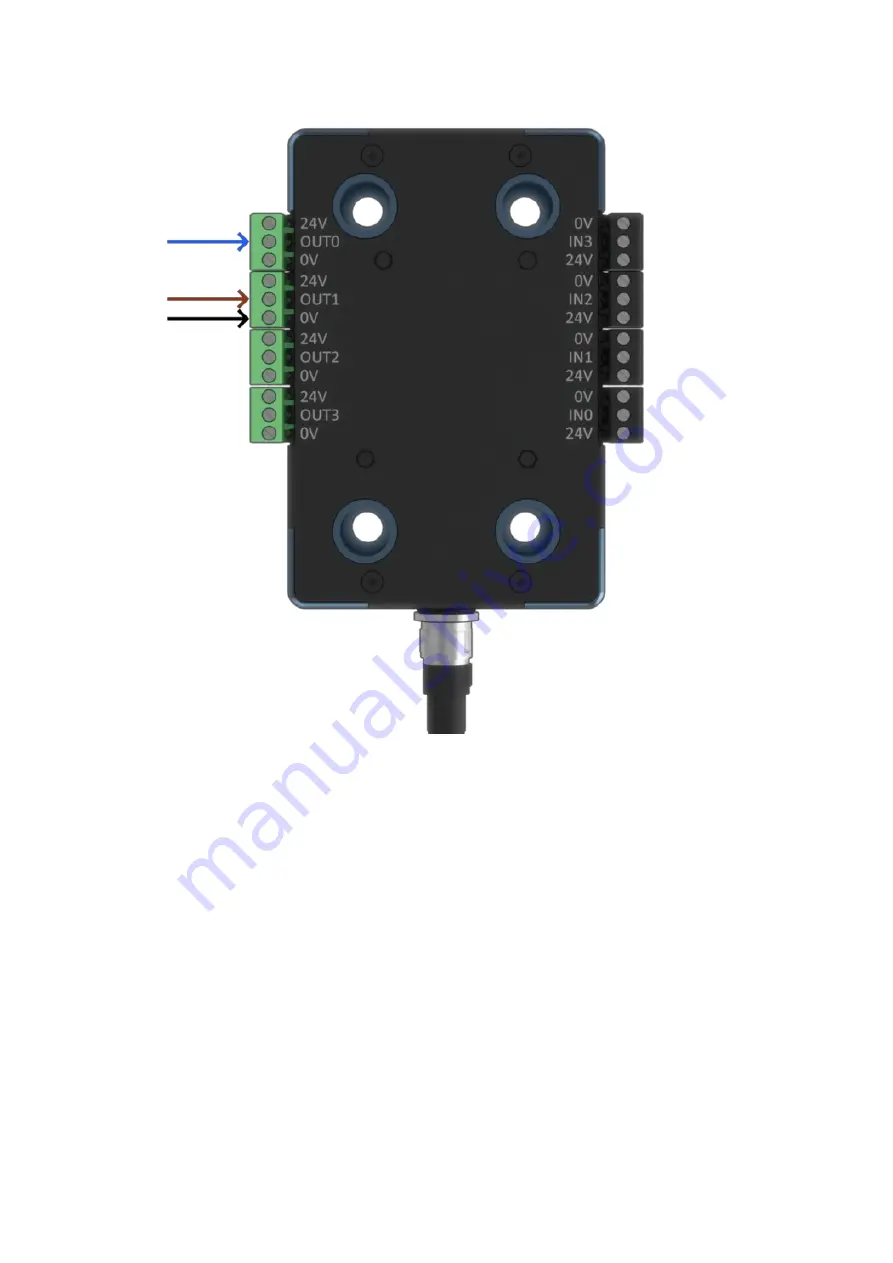

Figure 14: I/O Module

Light Curtain

The steps to connect the Light Curtain to MachineMotion 2 via the Safety Module are as follows:

1. Connect the receiver to the SAFETY RX connector using the Light Curtain Receiver Cable (CE-SA-106-0001).

2. Connect the emitter to the SAFETY TX connector using the Light Curtain Emitter Cable (CE-SA-105-0001).

3. Connect a MachineMotion 2 Safety Extension Cable (CE-CA-102-5001) to the Safety Module’s SAFETY OUT connector and MachineMotion 2’s SAFETY IN

connector.

4. If muting is required, connect the muting sensor in pairs to the Muting Sensor Y Adapter (CE-SA-107-0001). Then connect the adapter to the Safety

Module via the MUTING 1 and/or MUTING 2 connectors.

Note: If no other safety devices are being daisy-chained to the Safety Module, a safety jumper (CE-SA-102-0001) must be used on the Safety Module’s SAFETY

IN connector.

Summary of Contents for PR-DA-001-0295

Page 9: ...Figure 13 Laser Scanner Parent only wiring diagram ...

Page 14: ......