38

HE350 - Installation and Operation Manual

6.3.6.1

R Calculations

There are two ways to calculate the R factor of the floor protection. First, by adding the R-values of the

proposed materials or if some K and thickness values are given, by converting them to R values.

To calculate the R factor for a composite floor protection made of a combination of alternative materials,

simply add the R-values of those materials. If the result is equal to or larger than the required R value, the

combination is acceptable. For R-values of some selected materials, see

Table 1 : Thermal Characteristics of

Common Floor Protection Materials

*

Example: If the required floor protection R is equal or higher than 1.00. Proposed materials: four inches of

brick and one inch of Durock® board:

Four inches of brick (R = 4 x 0.2 = 0.8) + 1 inch of Durock® (R = 1 x 0.52 = 0.52). 0.8 + 0.52 = 1.32

This R value is larger than the required 1.00 and is therefore acceptable

In the case of a known K and thickness of alternative materials to be used in combination, convert all K

values to R by dividing the thickness of each material by its K value. Add the R values of your proposed

materials as shown in the previous example.

In the previous example: Four inches of brick (K = 4/5 = 0.8) + 1 inch of Durock® (R = 1 / 1.92 = 0.52). 0,8 +

0,52 = 1,32.

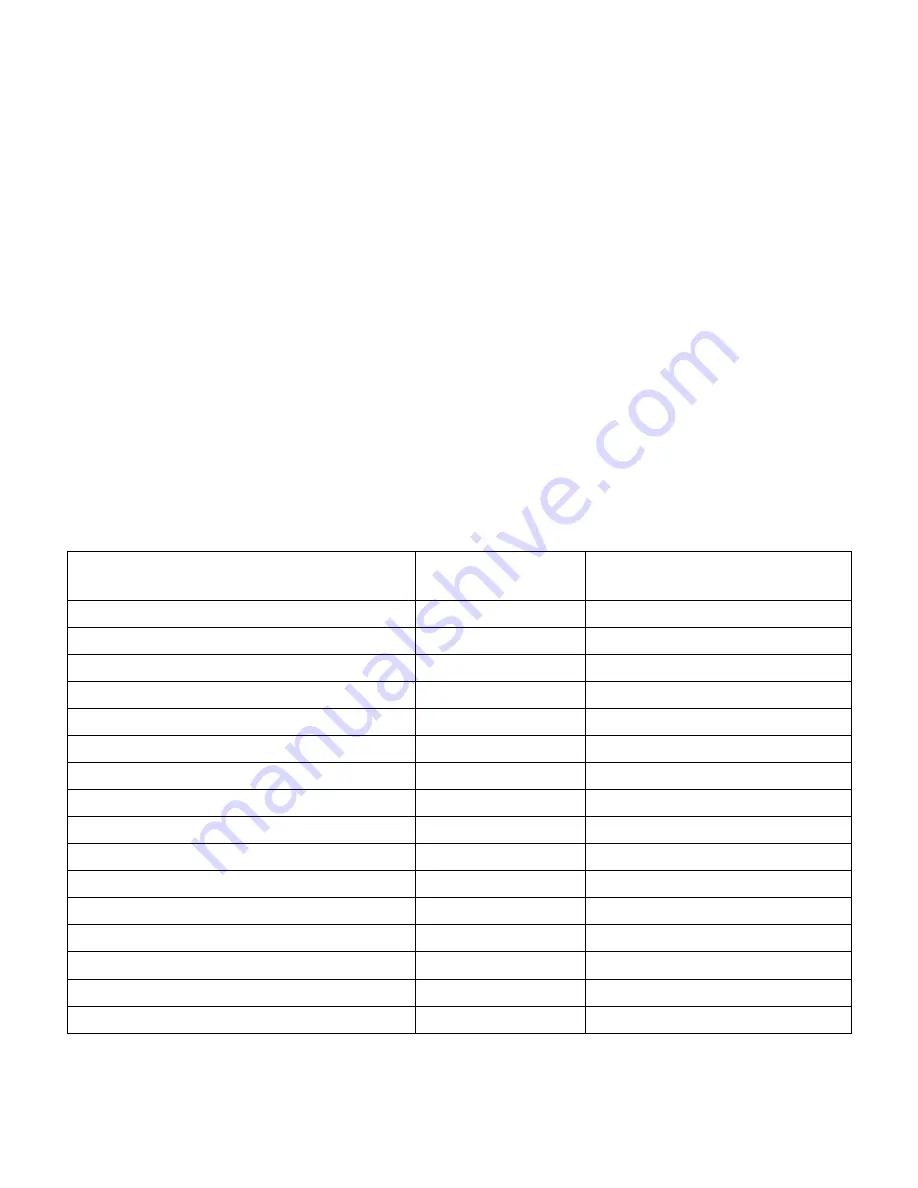

Table 1 : Thermal Characteristics of Common Floor Protection Materials*

MATERIAL

CONDUCTIVITY (k)

PER INCH

RESISTANCE (R) PER INCH

THICKNESS

Micore

®

160

0.39

2.54

Micore

®

300

0.49

2.06

Durock

®

1.92

0.52

Hardibacker

®

1.95

0.51

Hardibacker

®

500

2.3

0.44

Wonderboard

®

3.23

0.31

Cement mortar

5.00

0.2

Common brick

5.00

0.2

Face brick

9.00

0.11

Marble

14.3 – 20.00

0.07 – 0.05

Ceramic tile

12.5

0.008

Concrete

1.050

0.950

Mineral wool insulation

0.320

3.120

Limestone

6.5

0.153

Ceramic board (Fibremax)

0.450

2.2

Horizontal still air** (1/8")

0.135

0,920**

* Information as reported by manufacturers and other resources.

** For a 1/8" thickness. You cannot «stack» horizontal still air to accumulate R-values; you must separate each layer

of horizontal still air with another non-combustible material.